For example, the pharmaceutical industry is interested in the production of new medications with active ingredients at the nano scale. Active ingredients at the nano scale are taken up by the human body much more rapidly than conventional preparations; in other words, the better bio-availability makes it possible to significantly reduce the dosages in medication. Despite lower quantities of active ingredients, the same therapeutic effects are achieved while reducing undesired side-effects at the same time.

Nano particles are needed in materials research as well. For example, numerous research groups worldwide are active in the development of new nano materials for efficient storage of hydrogen. This is an important step on the way to the automobile of the future.

Sunken grinding bowls – premium performance

With the FRITSCH premium line planetary mill, the decisive step into the nano class has now been taken. The revolutionary new feature of the premium line is the sinking of the grinding bowls into the sun disk of the mill.

The grinding of materials down to the nanometer range requires very high application of energy and therefore significantly higher rotational speeds than those allowed by typical planetary mills. Conventional planetary ball mills are characterised by grinding bowls that are clamped to the sun disk. This limits the maximum possible rotation speed because as of a specific speed limit, the centrifugal forces acting on the bowls will be so great that the clamping of the bowls can no longer hold. Damage to the mill and the bowls would result.

Sinking of the grinding bowls into the sun disk of the mill solves these problems! Now, the centre of gravity of the bowls lies in the plane of the sun disk. The centrifugal forces arising generate significantly lower overturning moment, which in turn allows the mill to run at a significantly higher speed. As a result, the new FRITSCH premium line attains a speed of up to 1100rpm, generating up to 150% higher energy application. This significantly reduces the grinding time to reach the nanometer range. For certain materials, only this level of energy application even allows the creation of nano particles with planetary ball mills.

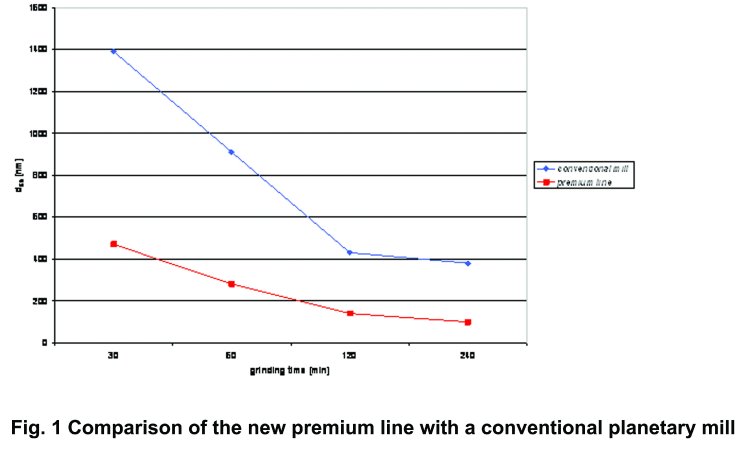

Fig. 1 shows a grinding test with the new FRITSCH premium line compared with a conventional planetary mill. Aluminium oxide Al2O3 was ground in suspension using 0.5mm zirconium oxide grinding balls.

The d50 value of the initial material was 21µm. After only 60 minutes of grinding with the FRITSCH premium line, the d50 value of the particle size distribution was under 300nm. This value is not reached with the conventional planetary mills even after 240 minutes. At the end of the test series (240 minutes), a d50 value for particle size distribution of 99nm was achieved with the new premium line. To generate still smaller particles, we recommend using even smaller grinding balls in a following step.

Time [min] premium line conventional mill

d50 [nm] d50 [nm]

30 450 1390

60 280 910

120 140 420

240 99 380

Table 1: d50 value depending on grinding time

SelfLOCK technology – premium safety

The sunken bowls also simplifies the handling and improves the process safety. The grinding bowls are clamped into the mill using the SelfLOCK technology with only two hand motions. Incorrect operation is impossible. An RFID-chip integrated into the lid of the bowl also automatically identifies the grinding bowls used. The rotation speed is optimized and impermissible grinding settings are prevented. Naturally, a balance check is integrated which prevents start up of the mill if it is loaded incorrectly.

The completely newly developed special bowls allow for secure sealing. Any overpressure arising during grinding can be released in a controlled fashion through a built-in valve in the lid.

In other words, the best conditions for achieving precise and reproducible grinding results down to the nano range.

Grinding programs and computer integration – premium simple

For routine operation, the premium line is naturally also capable of generating and saving various grinding programs. The variable parameters are speed, grinding time, pause times and reverse mode. It is possible to generate SOPs (Standard Operating Procedures) that can be protected with a password. The premium line has USB, Bluetooth and Ethernet interfaces for integration into the IT structure of the laboratory. Naturally, all grinding parameters can be recorded and saved by special software. This makes it possible to validate the grinding process.

Grinding bowls in the sizes 20ml, 45ml and 80ml are available for the new FRITSCH PULVERISETTE 7 premium line. A series of different bowl materials are available for the widest range of applications, of course. From agate to zirconium oxide, from steel to hardmetal tungsten carbide, the right material exists for every application. In addition, it is possible to select from an entire range of different ball sizes. It should be noted in particular that increasingly small grinding balls are also required in order to achieve ever smaller particle sizes.

The new planetary mill generation will be expanded already next year with the PULVERISETTE 5 and PULVERISETTE 6 premium line. The new concept described here will then also be realised for large grinding bowls up to 500ml.