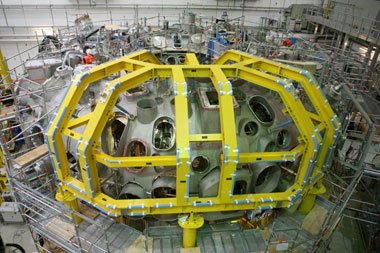

For this project Gantner Instruments has developed three measuring modules in cooperation with the Max Planck Institute based on new technologies which are not available on the market at the moment. These modules will allow measurement of strain values in a strong magnetic field and temperatures between room temperature and minus 270 degrees.

1. Measuring module e.bloxx A5-1CR for logging low temperatures

Special Cernox and TVOl cryogenic sensors were used to measure low temperatures beginning at 3 Kelvin. These sensors have special characteristics with a resistance of approx. 3,000 to 8,000 Ohms at 3 Kelvin dropping to approx. 30 to 100 Ohms at room temperature. The reading of individual characteristics is possible standard on all modules.

Due to the high number of measurement points in the field of cryo, the entry of performance acts in each sensor against a superconductivity. Therefore, this entry must be drastically reduced.

At a standard power supply of the sensor with a power source of 1 mA, the power on the sensor was 8 mW at 3 K and the measurement voltage 80 mV at room temperature. The performance of the sensor can be effectively reduced by a factor of 40,000 to 0.2 ĩW and reduced by a clocked supply current of 5 µA. However, a challenge is a robust, fail-safe and accurate measurement of the measuring voltage of only 0.4 mV at room temperature there. The precision of the measurement module must be able to accurately represent in a range of 40 mV a voltage of <2 µV. A series of tests on the IPP and other institutes have confirmed the suitability of the measuring module e.bloxx A5-1CR for this application in a real environment.

2. A101IPP measuring module

Special low temperature strain gages with half bridges were used for measuring the strain on the coil bodies. The knowledge gained from the series of tests resulted in continuously new requirements being placed on the measuring amplifiers during the course of this cooperative project. Since the strain gages were located in a strong magnetic field with values up to 6 Tesla, carrier frequency technology was used initially. Here, however, the microphonics effect resulted in vibration in the measuring lines (alternating current in magnetic field). Moreover it was also necessary here to minimize the power consumption on the half bridges. The solution was a pulsed bridge excitation voltage with special filters to guarantee soft on and off switching and thus a low dU/dt ratio. The test series was nearly completed when it became apparent that the special alloys at the power feedthroughs into the plasma chamber resulted in thermoelectric voltages at the contact points, which reached nearly the level of the strain gage signal voltages themselves. The objective was then to compensate these thermoelectric voltages to ensure pure stress measurement. The measuring cycle already established was supplemented to include additional measurement of the thermoelectric voltage during the strain gage measuring pauses when the excitation voltage was switched off.

3. Measuring module A107IPP

Modified A107IPP Q.bloxx modules are used at approx. 1,000 other Pt 100 measuring points.

The space required is also an important factor for a number of the 2,000 measuring points. With a width of 25 mm, the A101IPP Q.bloxx top hat rail module offers two and the A107IPP Q.bloxx module four measuring channels.

The modules are connected in groups to a number of Q.gate test controllers over a high speed serial RS485 interface. Here all data is logged synchronously, provided with a time signal and sent on to a server over a common instrument network.

The measuring systems are presently being installed; this trend-setting fusion reactor is scheduled to be put into test operation in 2014.