The single calculation modules of the eAssistant can be started directly from the menu integrated in the respective CAD system. The previous method of starting the calculation modules via a browser such as Chrome, Edge or Firefox, which required downloading a start file and clicking on it, is now completely unnecessary. The modules are launched directly without any detours. This increases convenience and speeds up switching between design and calculation.

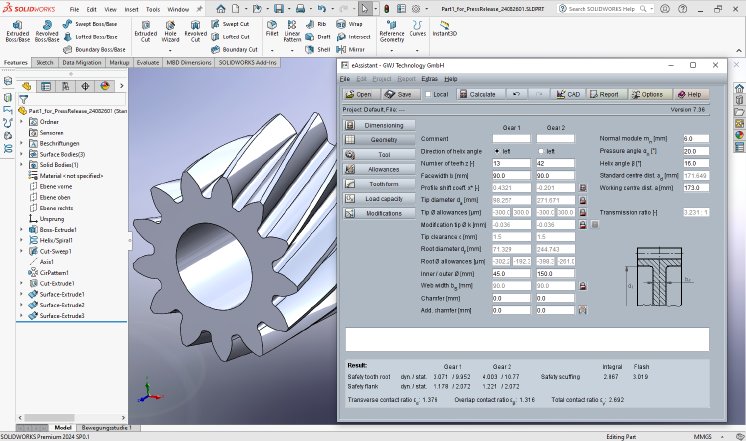

Using these calculation integrations or CAD plugins, the corresponding 3D models can be automatically generated directly from the calculations performed for cylindrical gears, racks, involute splines, bevel gears or shafts using the native functions of the respective CAD system. The tooth form of involute gears is created based on a mathematical manufacturing simulation, similar to traditional manufacturing using hobbing or gear shaping for a specified tolerance position. This means that the 3D models can be used directly for manufacturing, such as 3D printing, wire eroding, laser cutting, etc.

In addition, the calculation information is stored in the generated models. This allows the original calculation to be accessed directly from the 3D CAD model. The calculation can then be modified and the already created component can be adjusted.

In addition, spur gears or splined shafts/hubs can be cut into existing models.

It is also possible to automatically generate design tables with manufacturing data directly on the drawing. This eliminates errors in the transmission of basic gear and test data, and makes work faster and easier. These tables can also be customized using templates. Multiple templates for the same gear type are possible. The appropriate template can then be selected directly from a list box before it is placed on the drawing.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.