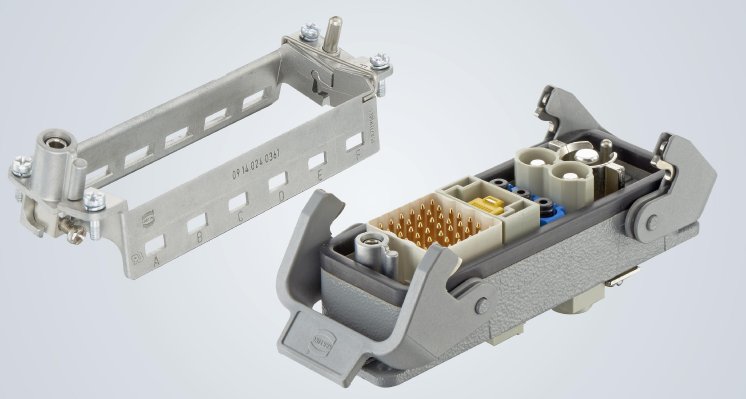

Highly visible lettering provides support in this context. All module positions (A to F) are evident at first glance, while an additional marking with a black triangle indicates the orientation for proper insertion of the modules on the frame.

Insertion of the modules is especially easy, since the spring maintains the frame in the open position and the modules fall into a defined support edge. The frame windows were optimised so that they have a funnel-shaped opening and the modules are automatically centred when closing the frames. When locking, a contour fitted to the joint works in tandem with the stainless steel spring to produce a clearly audible "click" and holds the frame securely together – meaning that hitherto used fixation elements can be wholly dispensed with.

Since the design of the well-known hinged frame was essentially maintained, it’s a given that it continues to boast particularly high mechanical stability and full compatibility with all Han-Modular® connectors, the market standard for modular industrial connectors.

This opens to customers the full variety of over 100 different modules for power, data and signal transmission. All available modules can be used without limitation, and no compromises need to be made in terms of mechanical stability. Nevertheless significant installation advantages arise for the user resulting in cost savings, since HARTING’s “Make good better” motto served as the impetus for several details to be improved. Once again, HARTING has set a new benchmark.