The Hannover Messe 2013 trade fair had already demonstrated the capability to equip transport containers with RFID transponders. The transponders were written with information describing the progress of production steps and were thus able to detect whether an order had been completely filled or whether parts were missing or if work steps had yet to be completed.

Now, the container's functionality has been extended by the addition of a temperature sensor. A temperature threshold is stored in HARTING middleware and is compared with the actual measured temperature reading, with the value written to the transponder. Upon reaching a threshold value, an alarm is triggered in order to prevent subsequent containers from being exposed to elevated temperatures.

Another type of container was constructed as an embedded system featuring integrated sensors. This system also has the task of measuring the ambient temperature and comparing it to a reference value, after which it wirelessly transmits the temperature profile of the transport path to a back-end system, where a decision can be made on any appropriate measures to be taken.

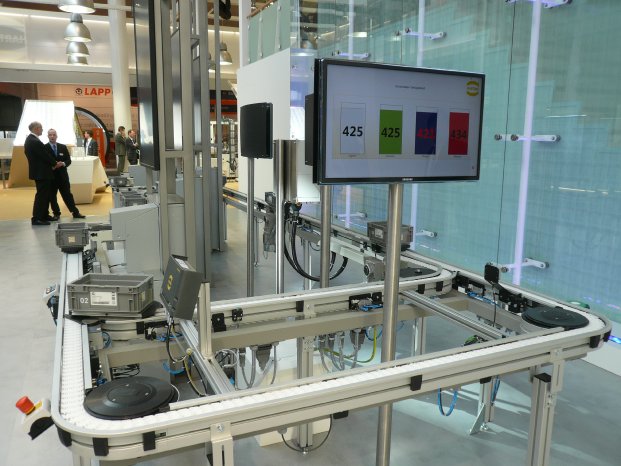

The container's position is determined via an integrated RFID reader. The data can be directly displayed both on the "monitoring box" as well as transmitted to a back-end system for visualization.

In both scenarios, if an alarm is triggered (by excessively high temperature) a worker can be instructed to immediately execute any necessary steps (e.g. lower the temperature, interrupt the production process).

What both scenarios have in common is that vertical integration has been continued and expanded within the enterprise. From the field level with RFID and sensors, all the way to the SAP back-end system, the systems collaborate in complementary fashion. Sensor data in the field is used as information to control production and logistics processes. As a result, an enterprise has the capability to be controlled via sensor data that originates in the production or logistics areas.