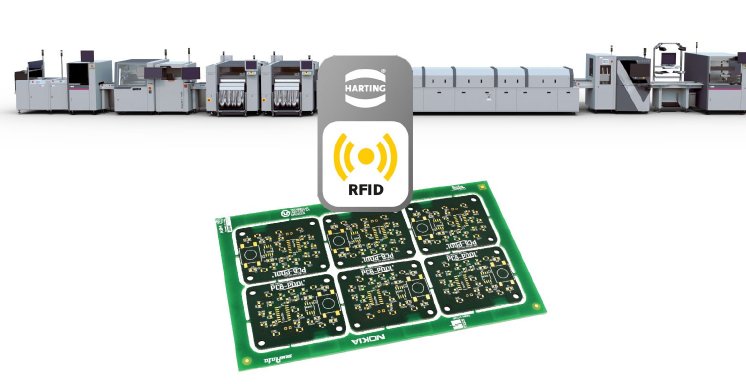

When the PCB is made, a small UHF RFID chip is inserted in the blank or attached as a component later on. From this point, manufacturing data can be written to and read from the RFID chip at each station in the manufacturing process. Even unplanned events such as machine malfunctions can be stored.

This is all enabled by the cutting-edge UHF RFID technology from HARTING, which will be presented at the "electronica" trade fair (13 to 16 November 2018 in Munich / Hall C2, Booth 548). Thanks to the coax-cable-based Ha-VIS LOCFIELD® antenna and the flexible UHF RFID reader Ha-VIS RF-R350 based on the MICA® platform, realisation involves a minimum of effort. The antenna field follows a coaxial conductor and allows communication with several PCBs in one PCB panel at full manufacturing speed.

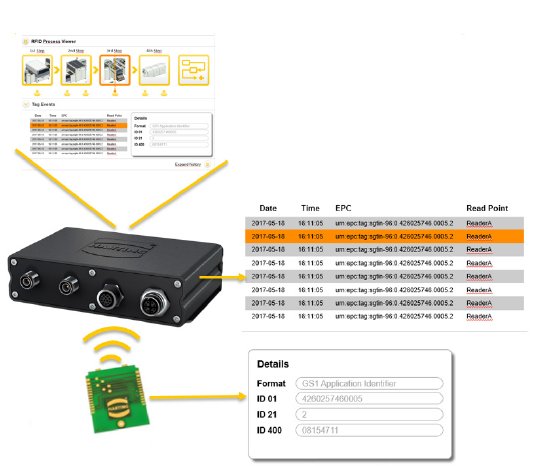

The reader and antenna can easily be integrated in new and old systems. The compact design and protection class IP67 also facilitate upgrading. Full data integration in the manufacturing system is therefore possible at any time, but not absolutely necessary.

Thanks to the modular and open software architecture of the UHF RFID read-write device Ha-VIS RF-R350, the data can be pre-processed in the reader. The data is stored in line with ISO standards and the GS1 standards applied to commercial goods transport. This is not only the case for the ID of the PCB itself, but also for the processing and manufacturing data stored in the user memory of the RFID chip. This is all transparent therefore and can thus easily be used later by a third party.

Using the ID characteristics of the PCB throughout the production lifecycle

Once the UHF RFID technology has been fitted on the PCB, it can be used throughout the lifetime of the PCB. It is possible for several PCBs to be read in bulk without optical contact, i.e. through foil and cardboard packaging, which makes the technology eminently suitable for warehouse and logistics processes. Furthermore, the information can also be read when the PCB is already installed in the application. Provided the housing does not consist entirely of metal and certain basic physical principles are adhered to, the information on the RFID chip can continue to be used and updated. The options offered by the UHF RFID technology remain available until the PCB is disposed of and can enable and improve a range of different applications.