RFID and digital information technology combined with the versatility of single-piece fixing ties facilitates the reliable identification and tracking of equipment across all kinds of industry scenarios.

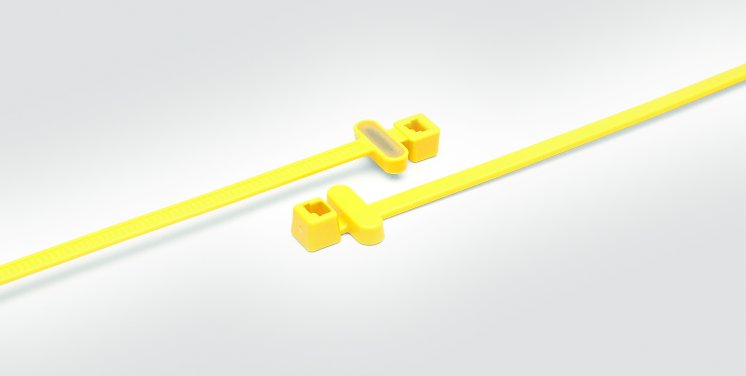

The RFID transponders are encapsulated in glass and embedded in the body of the nylon cable tie with UV-cured adhesive. This makes the tags extremely resilient to adverse environmental conditions, corrosion, vibration, shock and wilful manipulation.

In contrast to barcode labels, which can easily be rendered illegible under adverse conditions, the information on RFID tags can be read even without a direct line of sight.

RFID cable ties are ideal for inventory and tracking, helping end users save time with itemised scanning, whilst eliminating the manual data recording errors that are common along paper trails.

HellermannTyton T50RFID cable ties are available with low frequency (LF) or high frequency (HF) transponders. Each tag’s unique digital serial number can be read regardless of orientation and through most materials.

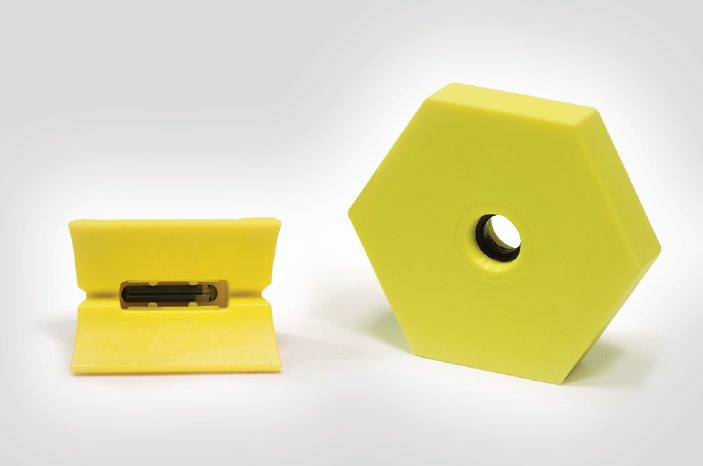

The complete RFID product range also includes extremely robust stainless steel cable ties equipped with HF and ultra-high frequency (UHF) transponders, plus HF tags embedded in plastic accessories which can be fastened with alternative fixing methods. Desktop and handheld RFID readers complement the portfolio.

With the aid of appropriate IT systems and reader applications, RFID cable ties can add a layer of data which enables the intelligent automation of business processes in line with industry 4.0 project aspirations.

HF RFID tags can carry customisable information beyond the unique serial number. They are also ‘NFC’ compatible and can be read using tablets and smartphones.