The specially developed ratchet closing mechanism is made from polyamide PA66V0 plastic that meets the rail industry EN45545-2 safety standards. The robust design and durable materials make it ideal for heavy duty applications.

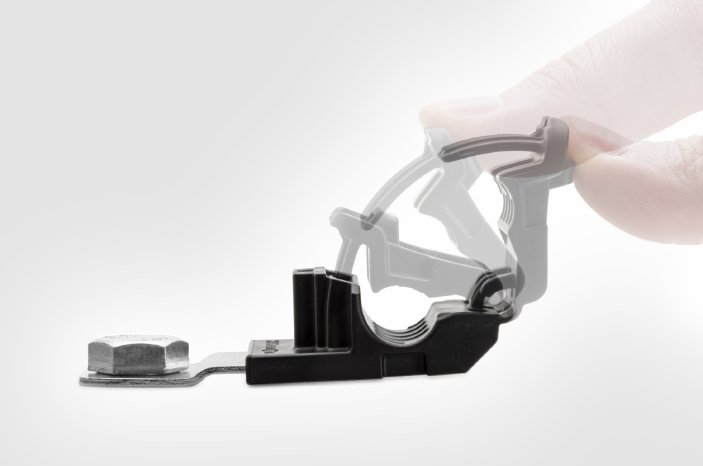

Where conventional p-clamps can be difficult to position, twist and pinch wires during installation and make the simplest of maintenance tasks complicated, the Ratchet P-Clamp can be pre-installed on a single fixing point before final cable or hose assembly.

The one-piece adjustable Ratchet P-Clamp clamp is available in four sizes (A, B, C and D), covering the most common 6.2 mm to 51.0 mm diameter range.

The ratcheting clamp is easy to close by hand to the precise diameter required. There is no slack and the rifling on the inside of the clamp automatically centres the bundle. Separate inserts provide strain relief, protect against abrasion or prevent corrugated conduits from slipping.

The mounting plate is available in stainless or zinc-plated steel in three lengths and four different angles, with M6, M8, M10 and M12 hole sizes, providing greater configuration freedom than conventional p-clamps. A handy fastening point for cable ties on the top of the clamp makes it easy to route additional cables parallel to the bundle.

The Ratchet P-Clamp can be reused time and again. The ratcheting mechanism can be released if required with the aid of a flathead screwdriver. There is no need for maintenance engineers to completely dismantle installations and they no longer have to carry a large range of p-clamps for specific bundle diameters.

A video presentation of the Ratchet P-Clamp can be watched here: https://www.hellermanntyton.com/downloads/videos?share=V9XOvPKgZ1s

Comprehensive details of the product series can be found on the following page: https://www.hellermanntyton.com/competences/p-clamp