The new kind of p-clamp makes it possible to fix wires, cables, hoses and pipes on a single mounting point in two separate work steps.

Till now installers have always found it awkward to hold the cables or hoses firmly in conventional cable clamps whilst they position and fix them securely.

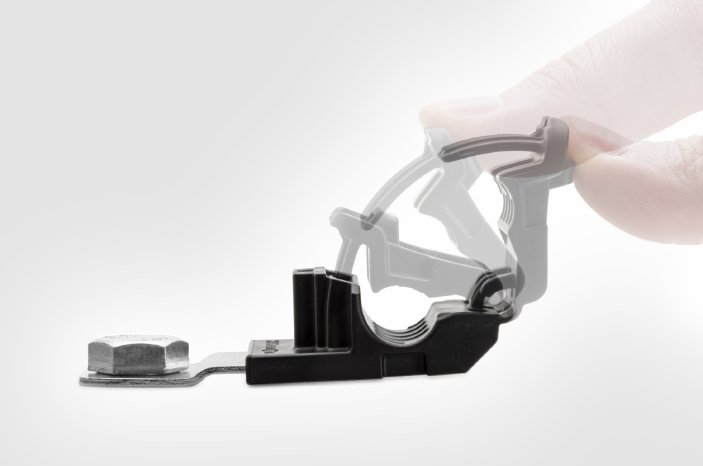

The construction of the Ratchet P-Clamp opens the way to a more efficient division of pre- and final assembly: position and fix the opened Ratchet P-Clamp first, then fasten the bundle, or conversely, apply the clamp to the bundle first, then fasten it to the mounting point.

The adjustable clamp is easy to close by hand to the precise diameter required. There is no slack and the rifling on the inside of the clamp automatically centres the bundle and minimises the risk of pinching.

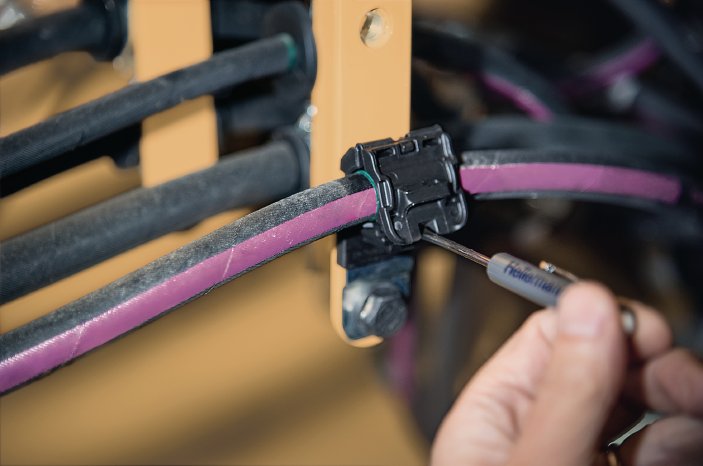

The Ratchet P-Clamp can be reused time and again. The unique ratcheting mechanism can be levered open if required with the aid of a flathead screwdriver. No screws or bolts need to be removed.

Maintenance engineers relish the fact that they no longer need to completely dismantle installations.

The Ratchet P-Clamp is available in four flexible sizes covering the common 6.2 mm to 51.0 mm diameter range.

The variability of the clamp diameter means that the part diversity of metal and plastic p-clamps with specific diameters in inventories can be reduced.

The design includes a cable tie saddle on the leading edge so that additional systems can be routed alongside.

The Ratchet P-Clamp is particularly suitable for fastening wires, cables, hoses and pipes in heavy duty applications like construction machinery, ships, trains, agricultural machinery or large industrial plant.

Soft inserts provide additional protection against abrasion of cables and hoses.

The robust Ratchet P-Clamp can be used at operating temperatures between -40 °C und +125 °C (up to +150 °C for 240 hours). The polyamide 6.6 plastic used is high impact-modified, heat and UV stabilised. The zinc-plated stainless steel mounting plate is suitable for high torque.

An optional tension tab used in combination with a HellermannTyton EVO series cable tie application tool makes it possible to close the clamp to precise tension settings predefined by quality assurance engineers.

Four different mounting plate angles, three lengths and four hole sizes for standardised M6, M8, M10 and M12 mounting bolts provide countless combinations and greater configuration freedom than conventional p-clamps.

Further product details are available on this web page:

https://www.hellermanntyton.com/competences/p-clamp

A video presentation of the Ratchet P-Clamp can be watched here: www.youtube.com/watch?v=V9XOvPKgZ1s