The formed-in-place foam gasket (FIPFG) sealing technology, i.e. the automatic application and curing of liquid seals, has been state-of-the art for many years in the highly automated vehicle construction but also during the series production of control cabinets.

With the FIPFG sealing technology, high quantities with the required zero error tolerance and with a repeatable product quality can be reliably achieved using the low-pressure mixing and dosing systems of Sonderhoff Engineering.

Liquid foam sealants are, in terms of contour and dimensions, precisely applied to industrial parts (with or without groove) produced in series and cure there to become a soft foam seal. Due to a usage of almost 100% of the raw materials, the material costs are kept to a minimum. In contrast to the pre-fabricated conventional inlay seals, there is no punching or cutting waste. Thus, the FIPFG sealing technology achieves high process safety and also quick subsequent processing times if Fast-Cure foams with a very short tack-free time are used.

Flexible production solutions and quick subsequent processing

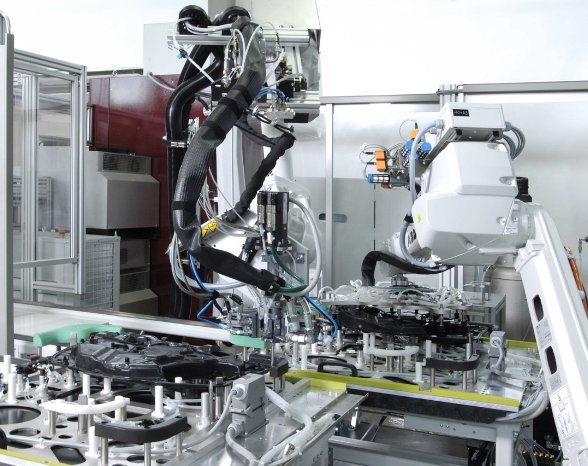

For sealing automobile door modules or control cabinet panels made of metal or plastic according to the FIPFG method, Sonderhoff Engineering, the machine manufacturer from Hörbranz in Vorarlberg, offers low-pressure mixing and dosing systems of the DM 40x series. The users may integrate these systems in a semi- or fully automatic manner into their production process either as a stand-alone solution or as a fully automatic production line. The Sonderhoff Mold'n Seal procedure allows for a process-integrated in-line production combining injection moulding and gasket application in a central place saving space.

The Fast-Cure polyurethane foam systems from Sonderhoff Chemicals used for gasket application of automobile door modules or control cabinet panels achieve tack-free times of less than 3 minutes at room temperature. This means the industrial parts can be quickly processed in the subsequent production process without requiring intermediate cost-intensive storage. Additional investments for furnaces are also not needed in order to accelerate curing reaction of the foam seals on the parts.

Good compression set of the Fast-Cure seal

The fast reacting Fast-Cure foam seals of the Fermapor® K31 FC product family have a low water absorption, and even some of them meet the protection class IP69K in mutual combination with the sealed part. Thanks to good mechanical values, they can be easily installed and reset 96 to 98% under test conditions at 70° C. This good resetting ability of the Fast-Cure foam seal is critical when a part, such as barrel lids and control cabinet doors, is frequently opened and closed in order to maintain a constantly high sealing effect in closed position.

Three- or multi-dimensional sealing application

When applying a sealing to a control cabinet door, the linear robot moves the mixing head of the mixing and dosing system along the part contour. Paste-like material is freely applied via the mixing head dosing nozzle to the inside of the control cabinet door. Once the sealing is applied, the foam expands to a size several times its volume and forms a soft foam seal with a width-height ratio of approx. 2:1. The ratio of width to height of a seal can basically be adjusted by means of the component material.

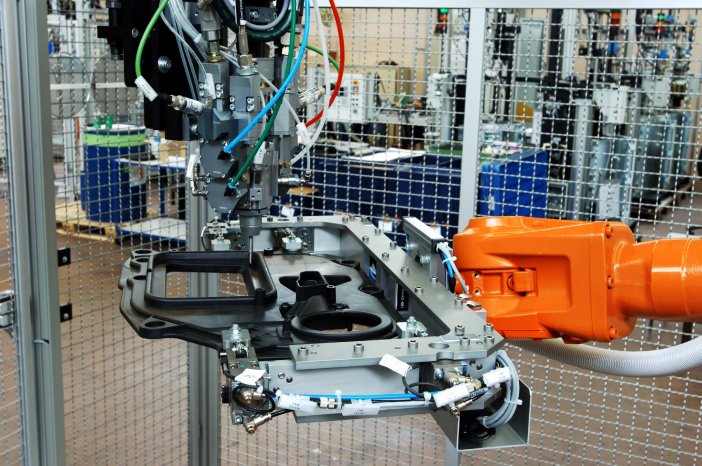

Regarding more complex three-dimensional parts with inclinations, the automatic sealing application may also be performed by an articulated-arm robot. Two configurations are possible in this regard: Either the robot grabs the part to be foamed and moves it below the mixing head of the dosing system or the mixing head is guided by the articulated-arm robot and precisely travels along the part contour for the sealing application.

Shorter production time due to quick subsequent processing

Regarding conventional foam seals with considerably longer tack-free times, control cabinet parts and automobile door modules must be cured on a longer curing line or even stored temporarily before being subsequently processed. However, by using Fast-Cure foam seals with very short tack-free times of 2-3 minutes, manufacturing companies are able to realize quicker subsequent processing and also an earlier start of the assembly of the parts. This results in significant savings of time during the entire production process, and thus, it contributes to reducing the unit costs and to make production more efficient.