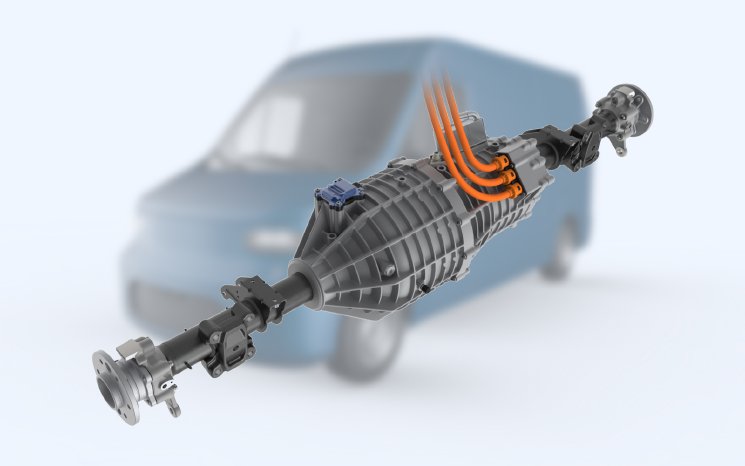

The ULTeBEAM's modular architecture supports both 400V and 800V configurations, offering maximum flexibility for original equipment manufacturers (OEMs) and pickup truck customers. This innovative electrified axle solution consists of a transmission and an e-motor connected to an external inverter, ensuring enhanced safety and performance. hofer powertrain offers engineering, design, and integration of such cutting-edge solutions, specifically tailoring them to unique customer requirements. Through close collaboration and adaptation, hofer powertrain is dedicated to ensuring optimal outcomes.

As the commercial vehicle market grows, there is an increasing demand for electrified and low-carbon solutions, particularly in off-highway applications such as mobile working machines. However, energy-intensive applications like harvesters and snowplows pose challenges for pure electric operation. hofer powertrain's ULTeBEAM approach addresses these challenges and strongly supports the market's engineering journey towards decarbonization.

With vast experience in mobile working machines and e-axle development for commercial applications, hofer powertrain is the ideal partner for OEMs. The company's engineering support covers everything from simulation-assisted design for outstanding functional safety to in-depth testing on advanced in-house test benches, industrialization, and beyond.

“The compact design of the ULTeBEAM solution aims to speed up the electrification of traditional rigid axle setups commonly used in commercial vehicles until today. This compatibility and similar architecture allow an easy and direct replacement, simplifying the electrification process for automakers and promoting a greener future for the commercial vehicle industry,“ closes Thomas HACKL, COO at hofer powertrain.