CAN bus line for low-temperature applications

Hradil Spezialkabel, your expert for special cables, has developed a low-temperature resistant and reeling CAN bus line with a small outside diameter. The cable has been designed for minimal bending radius and high data throughput in particular. This makes it ideal for high-bay deep-freeze facilities, i.e. for controlling stacker cranes with integrated video cameras. The CAN bus line permits the noise-free transmission of image data and control signals to the goods logistics department static-free, even at low temperatures and under mechanical stress. This means that status data on the location of goods and sequences can be transmitted to the warehouse management system via image processing. Automated processes enable the stacker crane to respond to the status and position the goods. Hans Haller, Hradil’s press officer, explains: “We have designed the CAN bus cable to be reeling, as well as suitable for industrial applications under difficult conditions. This opens up completely new areas of application for CAN bus systems, even at temperatures below freezing.”

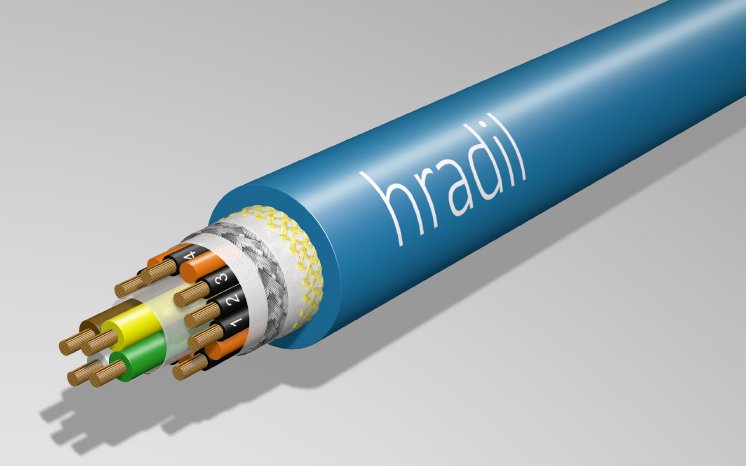

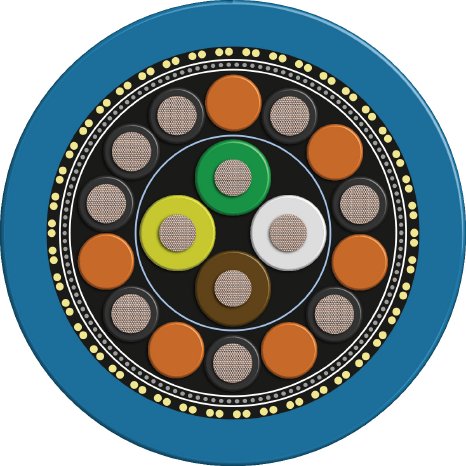

State-of-the-art cable architecture

The Hradil CAN bus line is distinguished by four features: reduced outside diameter, extreme resistance to cold, drum reeling and characteristic impedance of 120 ohms. In addition to the CAN bus core, the cable has further control wires.

It contains stress-free twisted cores, banding and shielding, some made from special PTFE film, and an open aramid braided sleeve with strain relief. The outer sheath is made of halogen-free TPE-U. The cables can be operated at temperatures between -40°C and +80°C and their tensile strength is up to 2,000 N.

The Hradil CAN bus cable is flame retardant in accordance with ICE 60332-1 and conformant with EU Directive 2011/65/EC (RoHSII). It is oil and fuel-resistant, as well as resistant against cooling agents and lubricants. Furthermore, it is ozone and UV-resistant, which makes it suitable for outdoor-applications.

What you need to know about CAN bus

In a CAN bus, components are connected to the joint data line, the bus, by short stubs. This means that relatively little cabling is required and that additional applications can be easily connected to the bus. An access process (protocol) is needed to control the flow of data to the various components on the common bus line. The controller area network (CAN) connects applications (nodes) using a two-wire twisted pair. The CAN protocol was developed by Bosch in 1983 for automotive applications. CANopen allows components from different manufacturers to work together. CAN bus technology is predominantly used in automation technology because it is highly immune to noise, low-cost and real-time capable.