Managing Director and company founder Hermann Schwelling welcomed the guests, mainly specialists from the waste disposal sector, at the company's headquarters in Frickingen. Representatives of the trade press and interest associations from the recycling industry were also among the visitors. With about 830 employees, HSM is active in the strategic business areas of office technology and environmental technology.

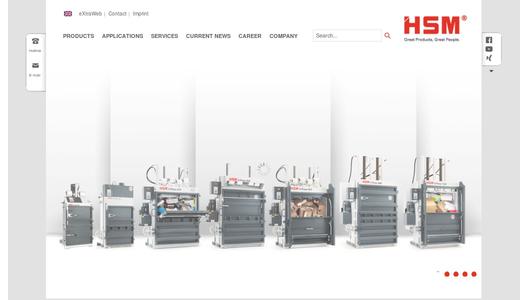

The product portfolio of HSM Environmental Technology includes vertical and horizontal loading-flap presses with a press capacity of 4 to 56 tonnes as well as semi and fully automatic channel baling presses with a press capacity of up to 150 tonnes. In addition, a variety of special solutions for emptying, perforating, crushing and compacting PET bottles as well as stainless steel dewatering technology are manufactured. Powerful machinery for data destruction in large quantities, e.g. document shredders and hard drive shredders, are an economical complement to the service portfolio of a professional waste disposal plant.

HSM places strong importance on customer service. At the Frickingen site, 15 qualified office employees steer the assignments for start-ups, maintenance and repairs, which are carried out by 36 service technicians in Germany and a further 38 technicians in various locations abroad plus 5 subsidiaries. The service personnel is continuously trained at HSM's own academy and other educational institutes. The close service network offers customers quick availability and short travelling times.

In recent years, HSM has invested approx. 4 to 6 million euros respectively in state-of-the-art manufacturing technology, buildings and process optimisations. Roughly 4.5 % of the turnover flows into research and product development. During a tour of the production plant in Salem, the visitors could see the high level of vertical integration and competence. Among other things, they were able to take a look at the modern paint shop, in which components with a length of up to 7 metres and a weight of up to 20 tonnes are sandblasted and painted or powder-coated. HSM also invested further in the automation of welding in 2015, and the seventh welding robot line with a load-bearing capacity of up to 12 tonnes has already been put into operation.

The participants found the presentation of one of the largest presses, the HSM VK 12018 R FU, very impressive. VK stands for fully automatic channel baling press, 120 for 1200 kN press capacity, 18 for the length of the filling opening (1800 mm), R for recycling, and FU for frequency-controlled drive. This drive contributes largely to environmental protection and to cost effectiveness. With it, savings of up to 40 % in energy costs can be achieved. It is available as an option for several HSM baling presses and multi-stage shredder plants, e.g. the TriShredder. A practical throughput rate of up to 32 tonnes per hour can be achieved with the "VK 120", as this shredder is also called, given a drive of e.g. 2 x 55 kW with frequency control. The bales weigh up to 1,000 kg and have a length of 1,200 mm. However, not only the weight but also the quality of the bales is decisive for disposers. The denser the bales are pressed, the more stable they are for storing indoors and outdoors, and the better they meet the requirements of the paper factories. The size of the bales is a further crucial criterion for disposers. At 1100 x 1100 mm, they offer a logistically ideal size for unloading lorries and containers.

The participants at the HSM Environmental Technology Disposer Day were very impressed by the concentrated competence and the extensive machinery on display and went home with a wealth of new and positive impressions.