Different load capacities are available for the POWER-Skates. The PSX 12-24 with 24 tonnes total load capacity and optional lift completes the range between the small POWER-Skate IDEAL 5-10 with 10 tonnes total load capacity and low installation height of 110 mm and the POWER-Skate 20-40, which has been available for many years, with 40 tonnes load capacity as a set, 180 mm insertion height and optional lift.

Simultaneous driving and steering at three speeds as well as safe precise positioning with the one-joystick function of a person's remote control are possible on three support points and are carried out proportionally. Due to their compact design, these transport systems are suitable for use in confined spaces. They have powerful, digitally controlled synchronous motors and a battery life of up to 4.5 hours under full load. The maximum insertion height is 180 mm.

Simple steering and constant directional stability in all areas and at all speeds is possible with just one joystick.The entire transport combination can be reduced by up to six meters, as the towing vehicle is no longer required as for a conventional transport process.

As a DUO version, two POWER-Skate XL trolleys can be moved synchronously using the Cerebellum DUO control system with just one radio remote control and one joystick.As a rule, an ECO-Skate ROTO rotation trolley is used as the third or fourth support point. This enables a total load capacity of 80 tonnes.

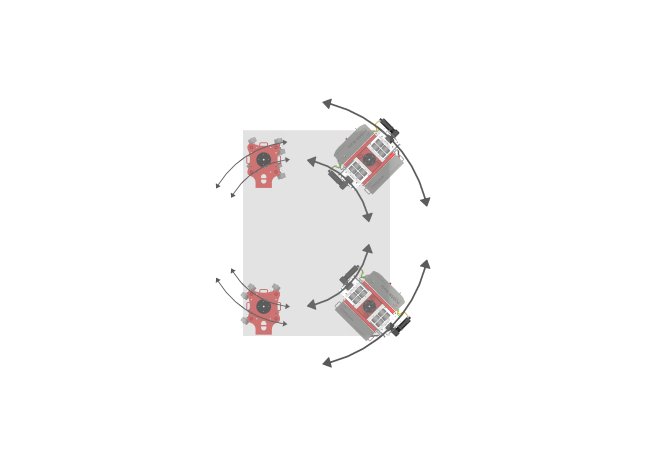

This synchronous transport process is particularly characterized by the fact that both skate units communicate with each other in order to coordinate the movement sequences such as synchronization or crab steering. Previously, the operator had to check the correct position of the transport units in relation to each other himself and readjust if necessary. The Cerebellum DUO control system enables automatic alignment by simply switching the remote control to a different driving mode. Transportation can begin as soon as the two skates are aligned according to the selected driving mode. This makes the application safer, as a visual misjudgement by the user no longer has any influence.As the load can be rotated on the spot, synchronized transports are often the only solution for very limited space conditions. Turned by approx. 180° or 90° in the production line or shifted sideways.

In addition, both DUO skates can be used individually with a set of rear skates for machine moving.