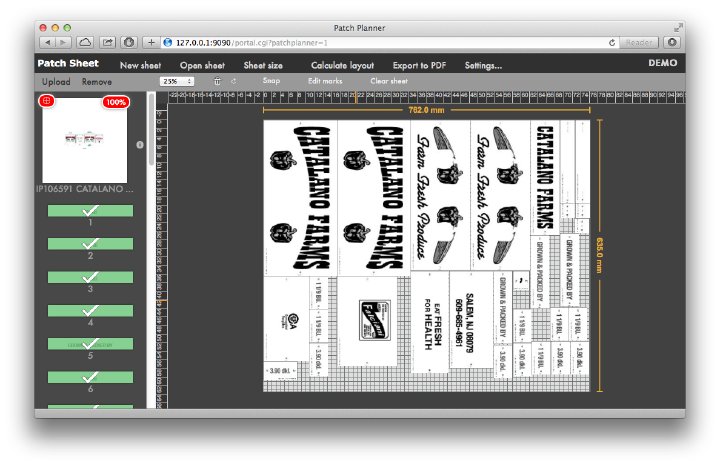

"Flexo plates are very expensive and anyone operating in a pre-press department will immediately see the attraction of Patchplanner," says Jan Ruysschaert, managing director of Hybrid Software NV. "When producing something like a corrugated box, it is not unusual for only a tiny area to need to be printed even though the box itself may be large. Until now a great deal of manual work has generally been required in order to avoid using large flexo plates.

"What Patchplanner does is to separate those printed elements in the design file and relay them so they take up the least amount of space. This data is then used to expose the smallest plate possible using an imager such as a ThermoFlexX. We can then send the information to a cutting table, for example, a Zund machine. Patchplanner software will control the cutting pattern, resulting in fast and accurate cutting.

"Using an AV Flexologic system the plate would then be reassembled on to a plastic carrier ready for the printing press. The high level of automation offered by these systems, combined with their speed and precision, makes this an extremely cost effective method of producing flexo plates for this sort of job.

"We've designed Patchplanner to be effective and easy to use," says Jan Ruysschaert. "The software offers cross platform support of standard web browsers - Chrome, Firefox, Safari, Internet Explorer 8 - and will output XML e.g. 'mom' files with mounting mark coordinates automatically transferred to AV Flexologic's Optimount."