Hybrid Software serves a truly hybrid world

Digital presses are here to stay, but conventional printing is not disappearing. Efficient print production not only requires good manufacturing practices, but also the craftsmanship and knowledge of traditional print developed over generations. Customers expect connectivity across all their hardware and software systems, but the IT environment where they operate is challenging and unforgiving. Hybrid Software operates at the nexus of prepress production and cutting-edge IT: The IT experts who know prepress, and the prepress experts who know IT.

The Heartbeat of Industrial Printing and Packaging

“Today we introduce a unified Hybrid Software built from six distinct operating companieswith one common mission: We are the heartbeat of industrial printing and packaging,” announces Guido Van der Schueren, Hybrid Software Executive Chairman. “It communicates our DNA to our customers and the industry; one of long-term mutual partnerships and a commitment to expert local support. We will continue to deliverleadership in software and electronics for industrial printing and packaging, driven by the intelligence and passion of our people, speaking the language of our customers, and sharing their heartbeat.”

Commitment to Innovation

Hybrid Software announced several major new products and technologies that will be demonstrated at their stand during drupa. They include:

MyCLOUDFLOW hosted SaaS workflow solution: CLOUDFLOW is Hybrid’s popular enterprise production workflow. The highly configurable enterprise production workflow system provides fast and effective automation of prepress tasks for more than 1,000 customers worldwide.

All demos at drupa will be run using MyCLOUDFLOW, a 100% cloud-based SaaS solution running in a dedicated Amazon Web Services (AWS) cluster. The No-IT solution offersquick access to CLOUDFLOW through a private and secure environment for each customer with strong data protection and immutable backups. Like any SaaS solution, there is no hardware purchase, and easy scalability without requiring local IT support. The installed base of MyCLOUDFLOW users grew steadily through 2023 as print providers accepted the power of SaaS and the advantages it can bring to their businesses.

Broadest 3D offering in the industry: CLOUDFLOW’s ProofScope tool for artwork viewing and approval has been enhanced with the addition of a 3D approval systembased on iC3D technology. Users can visualize product labels as well as embellishments like glitter and varnishes, applied directly to three-dimensional shapes including cartons and bottles. Hybrid Software will also demonstrate its new Capture3D software for accurate distortion of artwork for printing the highest quality shrink sleeves and die-formed metal packaging.

New MyPACKZ hosted SaaS PDF job editor and layout tool: MyPACKZ is a SaaS-based prepress application for any printing process, digital or conventional, derived from Hybrid Software’s very successful PACKZ software. PACKZ, with more than 5,000 copies sold, provides a full set of packaging prepress tools from preflight to step & repeat and trapping. MyPACKZ offers the same functionality in a hosted SaaS business model for increased production efficiency, quality improvements and reduced error rates. It’s the ideal editing solution for MyCLOUDFLOW customers, since it allows their files to remain in the cloud at all times, even when editing is required.

ColorSpace premium color management solution for labels and packaging: ColorSpace is a prime example of a Hybrid Software’s 100% ownership of technology for digital and conventional printing. Built on technology from its ColorLogic business, ColorSpace offers optimized color matching for digital and conventional print, to all users of PACKZ and CLOUDFLOW.

ColorSpace supports different color spaces, including CMYK, extended gamut CMYKOGV, and specific brand color inks. ColorSpace can offer non-experts—sales reps, CSRs and others—an automatic selection of the best ink configuration for each job on a given printing press, based on the smallest deviation from the spectral color (∆E), with reporting to MIS/ERP for accurate quoting.

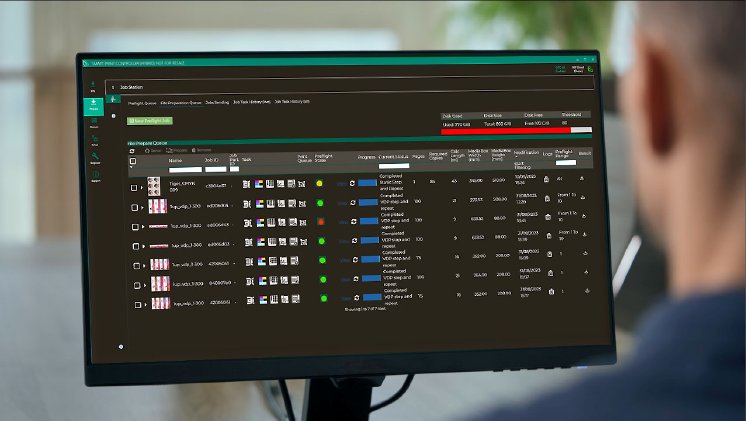

SmartDFE turnkey digital front end (DFE) for digital presses: SmartDFE, the 2023 Pinnacle Product Award recipient in the Technology category, is particularly targeted forhigh-speed, single-pass presses printing fully variable data. It is built upon Harlequin Direct, the world’s fastest PDF RIP and itself a 2021 Pinnacle InterTech Award recipient, providing rasterization and inkjet drop generation for the best possible image quality and quickest printing speeds.

SmartDFE provides high throughput while minimizing server costs by directly RIPping digital jobs to the printhead drive electronics, eliminating the need for expensive disk arrays. The distinct edge of Harlequin Direct comes from independence from third-party core RIP solutions, relying on Hybrid’s own proprietary Harlequin Core™—the world's fastest RIP core, as well as workflow technology based on CLOUDFLOW, and color management from ColorLogic – all developed in-house.

SmartDFE transforms the role of the inkjet printer. It not only helps OEMs build wider and faster digital presses, but also adds an outstanding print subsystem to a manufacturing operation or smart factory to produce mass-personalized products.

Meteor driver board for Epson D3000 printhead: Working closely with Epson, Meteor has developed scalable and reliable drive electronics to take full advantage of the benefits and features of the Epson D3000 printhead. This will be running live on the Hybrid Software booth at drupa.

Xitron IntelliTrap workflow solution: In prepress, trapping compensates for misregistration on press by creating overlaps of ink where different colors touch in printed designs. To resolve this, prepress operators typically rely on in-RIP trapping solutions that can result in insufficient control (especially with print jobs containing transparent layers) or manipulate the artwork manually. Neither process is efficient.Xitron’s next-generation trapping solution was co-developed with Hybrid Software for itsexpansive base of offset printing customers. Increases in job throughput by as much as 70% have been seen—especially with complex artwork. IntelliTrap is the perfect platform for effectively applying trap settings in prepress and is fully configurable for all offset printing conditions.

Key Partner Announcements

Hybrid Software also announced a number of projects with key cooperating partners. They include:

• Fujifilm: A workflow and SmartDFE front end for the new FP790 flexible packaging press (Hall 8b/A02–A02-6)

• AB Graphic International: Label finishing automation with FleyeVision integration

• Weigang: Printhead electronics and digital front end for its new high-end label press (Hall 4/D10)

• Koenig & Bauer AG: PrintFusion software for fast press setup (Hall 3/B31)

“Hybrid Software is the only company that can drive any digital printing press with its own technology developed 100% in-house. More than 100 Hybrid Software engineers have worked together to build the broadest product line in the industry. The result is a full stack solution for digital printing,” comments Mike Rottenborn, Hybrid Software CEO. “This represents all of the tasks required to manufacture print, from file preflighting and ink estimation, to prepress workflow and layout, to all facets of color management, RIPping files to the digital printer, overseeing inkjet printhead performance, to analyzing and reporting to networked MIS/ERP solutions. Yet, just as important as the technology is that we care, on a very local level, about the successes of all of our customers. We look forward to meeting visitors at drupa and helping them achieve exceptional print accomplishments.”

Hybrid Software is eager to welcome drupa visitors at their stand from May 28-June 7 in Hall 7A, Stand D03. Anyone who would like to schedule a meeting or product demonstration in advance can visit https://www.hybridsoftware.com/eventhub-event/drupa-2024/.

END

![SmartDFE LinkedIn_2024[89].png](https://cdn.pressebox.de/r/7b8f02c691b166f1/attachments/14/55/54/thumbnail_1455545_746x466.jpg)