During the last few years, in manufacturing companies, monitoring of the machine condition by means of Condition Monitoring (CM) has strongly grown in importance. With CM, you can develop condition-oriented maintenance plans and lower significantly production costs by using condition-oriented maintenance. In contrast to preventive maintenance, worn parts are replaced only if there is measurable wear. This way, you can prevent faultless parts from being replaced. Compared to reactive maintenance, the decisive advantage lies in preventing machine stand stills caused by defective parts.

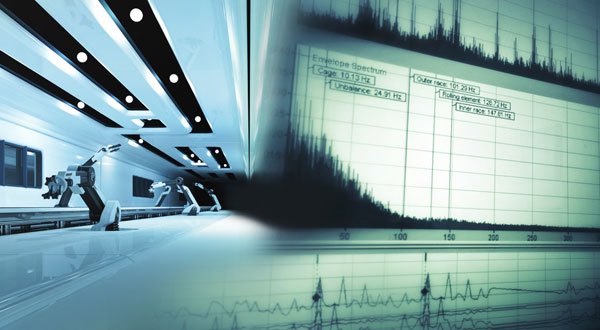

With the increasing size of the production plants, there is also an increased effort for condition-oriented maintenance. iba AG has developed a CM system that does not only monitor CM data, but all machine-, process, - material - and quality data, independent of the manufacturer. While ibaInSpectra compact offers a cost-effective and decentral isolated solution, the more powerful versions ibaInSpectra embedded and ibaInSpectra factory can be used for monitoring complex plants. ibaInSpectra embedded is especially made for machine groups and spectrum analysis for single machines. The biggest savings potential is achieved by using ibaInSpectra factory which monitors the whole machine park of a site over the whole production chain.

Currently, it is technologically possible to integrate Condition Monitoring into the automation of machines. Although this seems to be at first sight the more cost effective solution, it often implies problems. The data processing needs a considerable amount of system resources. If you withdraw these resources from automation, this might cause losses in the automation performance. Günter Spreitzhofer, responsible for Consulting & Applications at iba AG, strongly recommends employing Condition Monitoring as autonomous system. It does not only relieve automation, but also allows you to realize overall solutions for the whole site, which is a great advantage. Here, the overall connectivity of the Condition Monitoring systems supplied by iba has proven helpful. Spreitzhofer adds: "Automation based Condition Monitoring systems usually work manufacturer-specific. So, they deliver just partial information to the producer. The iba modules can be used independently of the automation system and the system generation. "

ibaInSpectra at a glance:

- Open interfaces to PLC and HMI

- Standardized CM solution for heterogenous automation environments

- Seamless integration of CM functionalities into the monitoring of the whole plant

- Acquisition of process-induced vibrations ("chatter") and defect frequencies of mechanical components like bearings and gears with the same system

- Monitoring of simple objects (e.g. fans, pumps) as well as complex monitoring solutions (e.g. planetary gears, acoustic test benches)

- Simple integration into database-based management systems

- Powerful analysis tool for the early detection of negative trends