The reason: The software can very well monitor the operation of the machine and ideally also optimize it. But it lacks a view of the environment – with the result that the supposed "problem machine" runs perfectly and consistently delivers top performance, but now the upstream and downstream processes cause problems.

The consequence of this: A software tool that optimizes only a single plant in interlinked production is clearly "suboptimal". Production planning systems, PPS for short, are used in many places. Although these are helpful, they only consider the manufacturing processes schematically sequential, comparable to a string of pearls. Dependencies between work centers, real-time data and time stamps are not considered here. Therefore, it remains a "theoretically" possible plan. Even with such a tool, bottlenecks can occur, as the more or less painful experience in many companies proves.

Optimizing the production process – but how?

Is there another way, that means a better one? Sure. One example: In a pilot project, an automotive manufacturer consistently collected and analyzed data in its body construction to optimize processes. The result: 15% more car bodies can now be produced per time unit. However, one must add: An entire team – including scientific monitoring – has worked on this project, and around two billion data records have been examined, correlated and evaluated with algorithms. This may be possible in automotive series production, but not in "normal" industrial production – apart from the fact that evaluating the data and implementing the findings requires a lot of time and expert knowledge.

Artificial Intelligence (AI) is required

The question that arises is: Is it possible to go one size smaller? This is where an AI-based algorithm comes into play, which is used to mathematically determine the best possible result in a prescribed computing time. The first algorithms already existed in ancient times and have proven their worth since then. Nowadays, such methods are used, among other things, for the evaluation of random samples. The new software tool GIB GXM Factory Optimization Excellence (FOX) is also based on an AI-based algorithm and thus enables simultaneous and optimal planning of all work centers in the plant.

Optimal and simultaneous scheduling of several machines or work centers

That doesn't sound spectacular at first. But to fulfil this function practice-oriented, the software must consider all requirements, dependencies, orders and capacities and put them in relation to each other. The volume of data to be considered is staggering. A team of experts as described above would take months to calculate: not an ideal situation for rolling planning or a planning horizon of one to two weeks.

Calculate the "best possible" production plan

The AI-based algorithm of the ifm solution ensures that all resources and requirements across all orders considered and across all available machines are combined into a real feasible production plan. The system then calculates another plan with the same data, compares the results and rejects the worse plan. The system calculates new production plans, compares them and keeps the better one until the given time limit is reached. The best plan at that time is then passed to the production planner.

But the intelligent algorithm is only part of the groundbreaking ifm solution because even mathematics at the highest level needs the right data. In the so-called "pegging", the dependencies of all work centers are determined for each order to be processed in the period under review. This also includes time stamps, for example, downtimes and set-up times. In pegging, the complex network of manufacturing operations is "unraveled" and can then be used to calculate the production plan.

The combination of AI and pegging brings clear advantages

The advantages from which users of the new planning tool benefit are obvious:

- The use of resources can be planned much better and thus waste can be stopped. An example: A bottleneck machine causes a jam in the production flow. The consequences: The order cannot be completed on time, the downstream machines and workers are at a standstill, and the intermediate products from the upstream processes have to be stored temporarily. This costs storage space and empties and increases capital commitment. And this can, as seen above, be avoided.

- The throughput is accelerated because waiting times, downtimes and set-up times are coordinated. This reduces operating costs and ensures even capacity utilization. In addition, Overall Equipment Effectiveness (OEE) is increased and overall output raises without having to increase production speed to critical areas or arrange extra shifts.

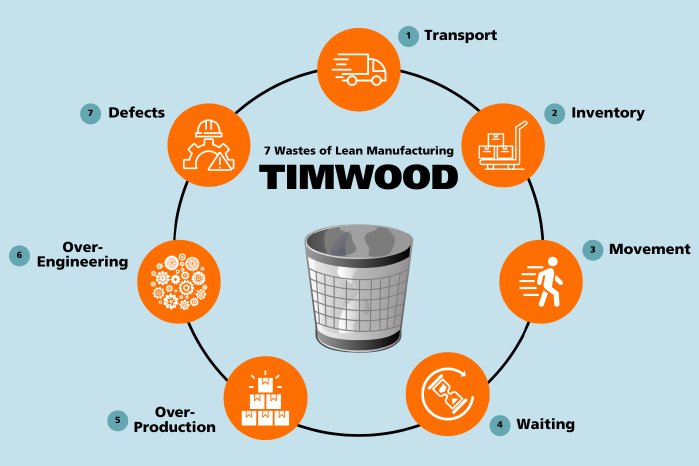

More precisely, the new software offers sevenfold benefits. That's because it addresses each of the seven types of resource waste that exist in the supply chain. These wastes are known by the acronym "TIM WOOD": Transport, Inventory, Movement, Waiting, Over-Production, Over-Engineering, Defects.

A concrete example from manufacturing:

- Transport – Parts and materials are transported from one place to another

The material supply to the work center is adjusted to the production plan in terms of time and capacity. This avoids waiting times, material bottlenecks and oversupplies.

- Inventory – unfinished (intermediate) products or components; warehouses of vendor parts

Instead of building up buffer stocks to bridge "feared" bottlenecks, all orders are manufactured in time. Less inventory means lower costs.

- Movement – Unnecessary movements of employees or machines

Instead of constantly working on disruptions in the process and thus only playing fire department, materials and people can be used optimally and stress-free. Workarounds as a result of disruptions are obsolete. - Waiting times – e.g. for delivery of purchased parts or intermediate products

Delays due to jams in the production process belong to the past. - Over-Production – Production "on stockpile" without (internal or external) customers

The user does not have to plan buffers for supposed bottleneck machine systems. This manufactures based on "real" orders.

- Over-Engineering – Adding features that do not bring value

Instead, the algorithm determines a solution that provides high efficiency within a performant time limit and does not strive for a perfect plan, but for the best strategy. At the same time, it remains "lean" and does without complex analysis options, for example, which have a counterproductive effect on transparency and usability.

- Defects – Parts must be reworked

Sudden changes in plans, rescheduling of resources to other machines and work centers and unplanned downtimes: Such irregularities often lead to errors in production. This can also be avoided by combining AI and pegging.

In all seven "pain points" of the internal supply chain, the new software tool can reduce waste and optimize the use of existing resources. This applies to the "stand-alone" operation of GIB GXM FOX and – to an even greater extent – also to its use in combination with other IIoT tools from ifm, which address the topics of maintenance and track and trace quality, for example. The tool is also recommended as an add-on to the core GIB products, which, among other things, identify dead stocks as well as surpluses and shortfalls, optimize ranges and balance safety stocks.

By: Gerald Scheffels for ifm

Would you like to learn more about GIB GXM FOX and how our other products and services can support you in the areas of "avoiding waste" and "more sustainability"? Then don't miss our annual SCM symposium, the ifm SUCCESS DAYS!

The event will take place on May 23 and 24, 2023. This year's motto: "The impact of change – How much can your supply chain take?". Register now and join us either on-site at the Apollo Theater Siegen or via digital livestream!

https://ifm-business-solutions.com/...