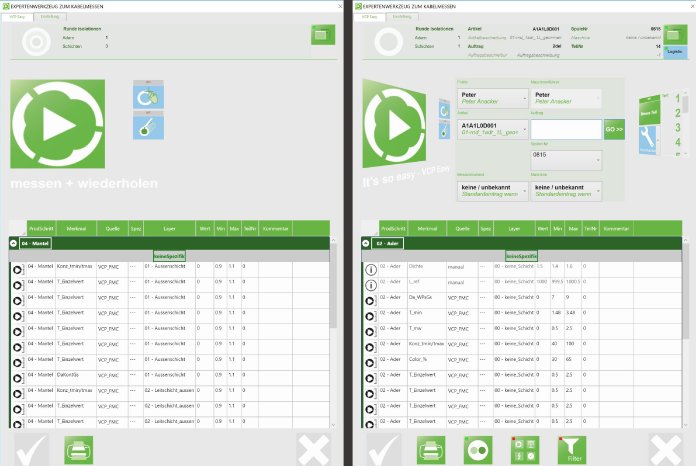

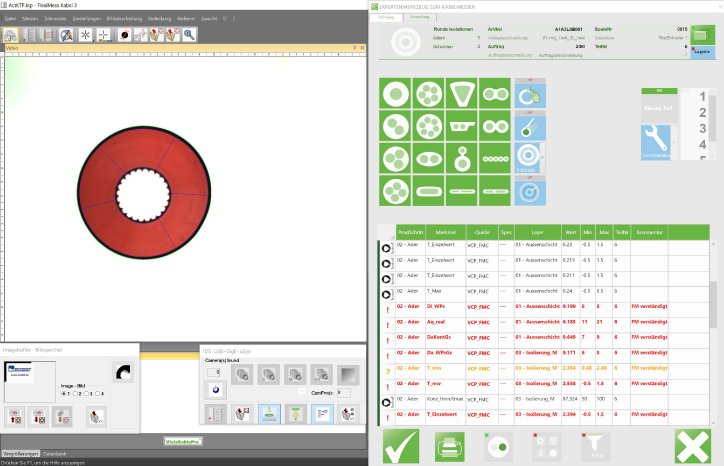

The primary goal of the cable measuring device VCPX5 and the measuring software VCPEasy that goes with it is standard-compliant measurement of the geometries of insulating jackets and cable sheathing in just a few extremely straightforward steps. The diversity of the areas in which cables are used and the resulting abundance of cable variations mean that there are very individual requirements for this measurement method. The team behind the VisioCablePro® brand set themselves the task of developing a complex solution package for all of these special requirements that is extremely easy and intuitive to use. In combination with the VCPEasy software, the proven VCPX5 can therefore now be used both in the laboratory and directly in cable production. The extensive measurement capabilities of the well-established FlexiMessCable 3 software, or FMC-3 for short, are retained. In addition, the new version of VCPEasy includes the ability to measure customer-specific special geometries. The software also calculates other important characteristics, such as the volume and overconsumption of the material used. For cable manufacturers, these features are a big advantage when it comes to material savings. The software’s open interfaces enable smooth communication with other measuring devices on the factory floor, such as resistance bridges or tensile testers. The VCPX5 cable measuring device and the VCPEasy software therefore come together to form a central measuring unit that can be operated by almost any machine operator. The VCPEasy user interface is both optimised for touchscreens and flexibly configurable, allowing the controls to be reduced to a minimum if needed. (Figure 1)

In practice, this results in precise cable measurements that are not influenced by the operator and are in accordance with standards such as IEC EN 60811. VCPEasy can be used to set up different operators with their individual logistical information on the VCPX5 measuring device, making it easy to measure different cable lines on just one device. During the measurement processes, marking based on the traffic light principle can be used to determine at a glance which values are within the action limits and in the tolerance range and which values require adjustment. The optical marking is used in all measuring and calculation processes. (Figure 2)

In addition, the operator can make manual report entries, for example the results of the tight fit check, into the automatically generated report. Alternatively, however, other measuring devices such as resistance bridges or tensile testers, which supply measured values automatically, can also be connected directly. This makes VCPEasy suitable for use as a central program for the collection of a wide range of test data in the area of cable measurement technology, pooling all relevant information in a single document.

All in all, the VCPEasy software solution can be used for any procedure for geometric cable measurement. Different operating modes are available depending on customer requirements. Whether the test plan is being read in before the start of the measurement, an externally integrated CAQ system (Aesa CIQ, Advaris etc.) is providing the required test plan or you are using the CAQ system ProCable 3, which was specially developed by iiM AG and contains numerous test plans in its database – VCPEasy offers the right interface. Please ask for details about the possibilities for use of the VCPEasy software and other products in the VisioCablePro® series at this year's WIRE. iiM AG cordially invites you to visit our booth at exhibition stand 9C49.