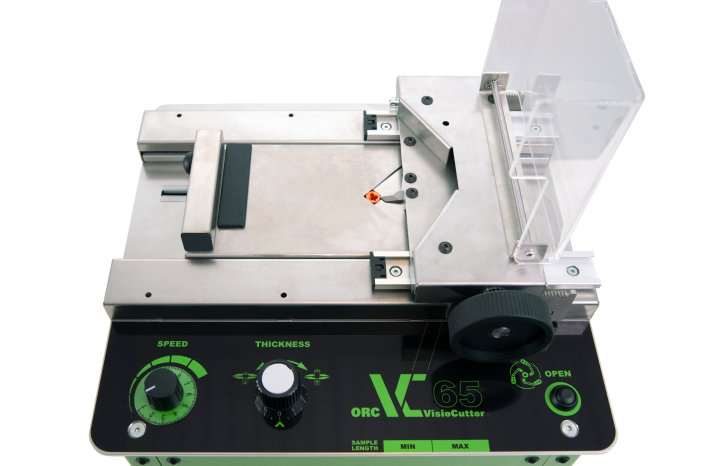

The current economic situation is marked by high costs, supply chain problems and staff shortages. As result of that it is even more important to save valuable resources with the help of efficient devices and solutions. The VisioCablePro® brand team has set itself the task of supporting manufacturers of extrusion products by using professional devices and software on all aspects of quality assurance, thus saving costs, time and material. In most cases the quality assurance process begins with the preparation of samples of the extruded product. Since precise and consistently uniform samples are the basis for reliable measurement results, hence the use of the new O-ring cutter ORC VC65 is essential at this point.

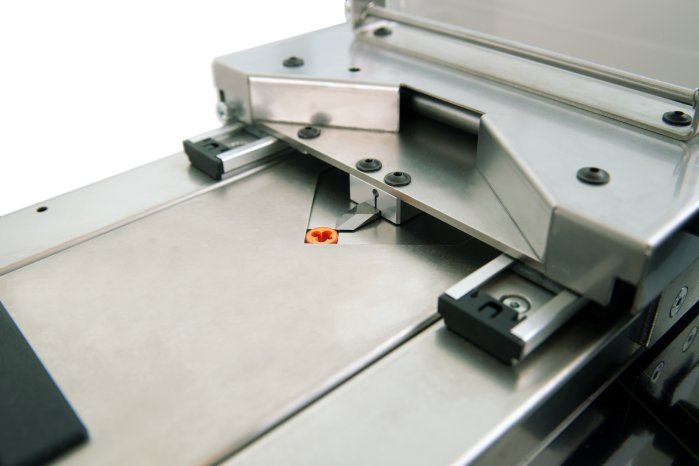

The new cutting device delivers a highly improved sample quality through a precise and reproducible sample thickness. When using the ORC VC65, the preparation is in accordance with the IEC 60811 standard. Samples with an outer diameter of 1 – 65 mm are easily cut by a manual and fine dosing of the progressive feed. The VC65 is also suitable for a wide variety of materials such as rubber, PVC, PE, plastic mesh and much more. This is made possible by a special two-sided steel blade by VisioCablePro®.

A firmly defined blade feed minimizes the influence of the operator at this point and thus guarantees a safer cutting process. The intelligent control electronics also ensure intuitive and, above all, a safe operation of the ORC VC65.

The new cutting device from iiM AG is ideal for preparing samples for qualitative measurement on offline measuring devices. A compact size and low weight are ideal conditions for use in the laboratory or at the production lines. Find out more about the possible uses of the ORC VC65 and other products from the VisioCablePro® series at this year's WIRE. iiM AG cordially invites you to visit their booth 9C49.