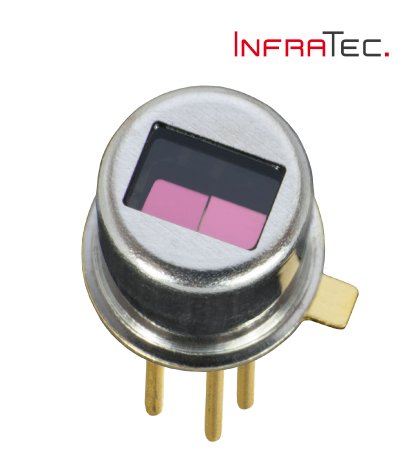

Just like the premiere model of the series, these latest developments are also characterised by their innovative design. The IR filter is directly above the pyroelectric element in the centre of the detectors. This saves important space when assembling and improves the protection of the filters against external influences tremendously. This layout means that the optical channels are close together, the optical performance increases and a greater signal-to-noise distance results. For this reason, the TO46 family LRM-102 and LRM-202 are characterised by high-quality signal transmission.

Another result is the significantly increased field of view (FOV). The reason for this, apart from the reduced distance between the filter and pyroelectric material, is a large central window integrated in the cap. This replaces the filter relocated to the inside of the detector. It is made from robust material such as silicon and effectively prevents the penetration of moisture. If the window is soldered in the cap, this even results in complete hermetically sealed protection.

The compact design of the detectors still allows users lots of scope for individual adjustment. Thus, the stack formation of the micro-electro-mechanical systems, for example, opens up the possibility of thermal compensation. The miniaturized design also offers the advantage of cost-optimised production from which users benefit directly. You get a solution for gas analysis and leakage detection that can be used in stationary and mobile devices ranging from medicine to safety technology and convinces with an attractive price-performance ratio.