According to IPH engineers, communication between man and machine is about to become much easier due to a new super label they have been developing for the past two years. Since spring 2011, they have been examining how existing automatized identification systems (auto-ID systems) can be combined in one single system. Their newly developed all-in-one label offers all advantages of existing auto-ID systems: On one hand it can be read by people, on the other hand, like a barcode or QR, it is machine readable. Additionally, information saved on the label can be changed afterwards, just like information saved on an RFID tag.

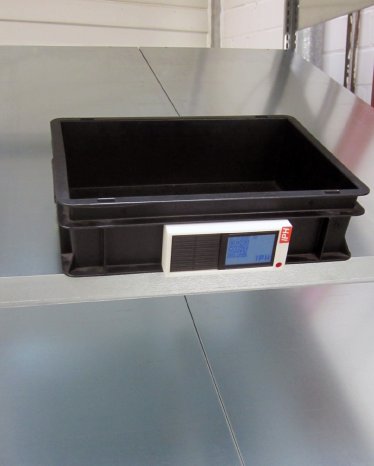

Eligible for all companies handling goods and material, the new all-in-one label might be used across various branches. In warehouses, for example, it can be utilized to mark boxes. At present, staff has to use special devices such as barcode readers to decode matrix codes. The super label, however, displays both code and letters. Since both man and machines are able to get the information immediately, the all-in-one label may help to facilitate co-operation and communication. Thanks to VLC (visual light communication), information can be changed quickly with the help of a smartphone. The LED light of the sender transfers an optical signal with a wavelength of 660 nanometers. By the human eye, this signal is perceived as red light.

Visitors of the HANOVER TRADE FAIR will be able to test the new label in a realistic warehouse environment. From 8 to 12 April 2013, IPH exhibits its new all-in-one label at the joint booth of research institutes and SME of Lower Saxony (Niedersaechsischer Gemeinschaftsstand) in hall 2, booth A10. Visitors will be able to read out and rewrite the super label on site with their own smartphone. IPH has developed an app based on Android that can be downloaded for free. Once information saved on the label is modified, changes can be observed on the display.

The all-in-one label has been developed in a research project that will end on 30 April 2013. Afterwards, the label will be tested in practice. IPH is searching for companies interested in trying the system. In the months to come, IPH engineers are planning to further develop the technology. Until now, the reach of the red light is limited to only one meter. Since the display reflects light, it is hard to read the information presented on it. Also, to ensure energy self-sufficiency, the engineers are planning to integrate a solar cell to provide energy to the display.

The research project "Auto-ID mit sichtbarem Licht in der Intralogistik" (Automatic identification using visible light communication in intra-logistics) was managed by Arbeitsgemeinschaft industrieller Forschungsvereinigungen "Otto von Guericke" (AiF) e. V. on behalf of the Forschungsgemeinschaft Intralogistik / Fördertechnik und Logistiksysteme (IFL). It was funded by the German Federal Ministry of Economics and Technology.