In the metal industry, global competition is boosting pressure. That is why the production speeds have to increase, quality has to improve, processing times are becoming shorter and especially the earnings have to be maximized. Fully automatic inspection systems make an important contribution because they generate large amounts of important quality data. The networked monitoring and documentation of individual process steps help optimize automated processes. But this is only a first step.

The key to increase productivity and to maximize cost and time savings is somewhere hidden in all the Big Data of the company, even in the quality data. Using an intelligent and well-founded analysis and evaluation of all relevant information earnings can be increased even more clearly.

Secure quality decisions at every corporate level

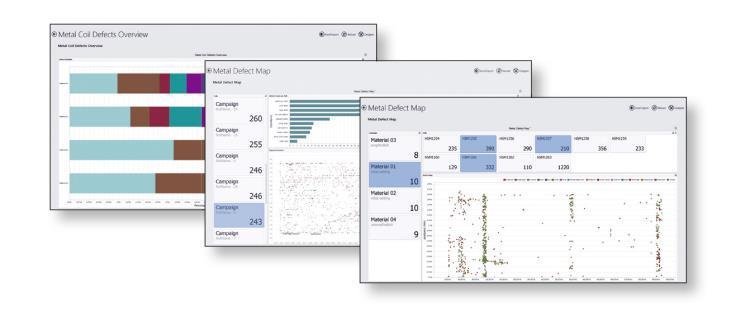

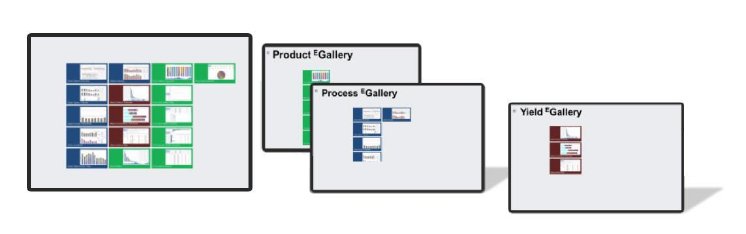

With EPROMI ISRA VISION now presents an appropriate solution suite for these tasks. Here EPROMI stands for Enterprise Production Management Intelligence and that can take the metal manufacturer literally. EPROMI analyzes different production and quality data and generates this way valuable information out of them such as defect causes at the plant floor. Using so called cockpits based on integrated expertise secure management decision are made possible. With these cockpit's, which exactly match the requirements of the management, production yield can be maximized goal oriented. The decision-making process of the management is supported based on secure information, easily generated at a fingertip. Here, the user can choose between predefined cockpits for process optimization, based on ISRA VISION know-how and those creatable to specific personal needs. This is made possible with a powerful tool the so called EDesigner.

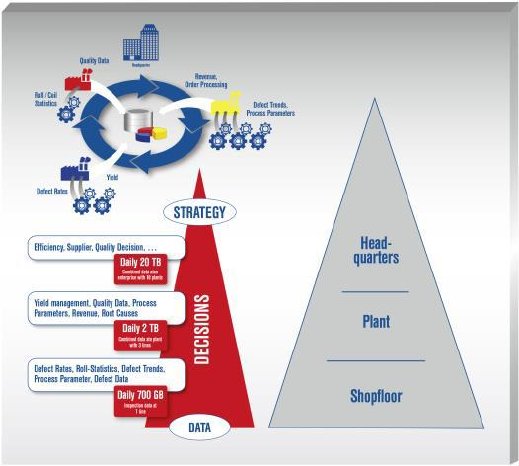

The cockpits utilize different data from various sub-divisions, for example, coil statistics, defect rates, order and sales information as well as process parameters. These data are combined and set in relationship for a better understanding of processes. Using the analysis of the combined data, decisions can be optimized and strategies can be developed to achieve higher production efficiency.

The daily generated terabytes of quality information are analyzed by EPROMI with the aim to optimize decisions and finally to enable strategic conclusions for process optimization on line, plant and enterprise levels.

Statistical process control to optimize production

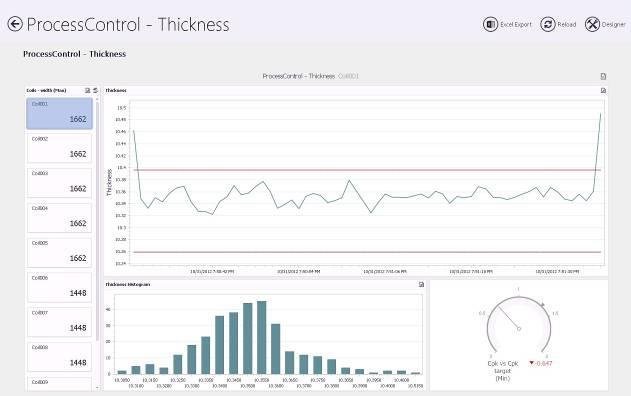

An example application of EPROMI represents the world's first statistical process control for continuous processes in the metal production. This application, known from the piece manufacturing technology, allows a procedure for optimizing production processes based on statistical methods. After the process and the desired production goals were clearly defined, the corresponding units of measurement and quality data must be determined. For this, surface defects, coil data such as thickness and width as well as the chemical composition of the material are usually to be used in a rule. So for each piece produced metal all qualifying parameter will be exactly analyzed. This information leads on the one hand to information, how well the production process is in a particular partition, and on the other hand, which amount of high quality is possible.

EPROMI thus helps manufacturers to achieve their goals by defining the internal quality specifications and tolerances. For example, for automotive manufacturers, the thinnest sheet steel can be produced, which complies with all relevant quality parameters safely. The earnings will be sustainably maximized. The production process corresponds to the ideal economic criteria with the highest customer satisfaction. The predefined quality parameters of the coils are met costeffectively. An above and beyond the required level quality level would result in additional costs for the manufacturer to follow, which would be associated with only an insignificant or no additional benefit. Thus EPROMI makes a decisive contribution to higher resource and energy efficiency.

The example statistical process control shows: EPROMI is already applied industry 4.0. The intelligent production uses completely networked data to optimize valueadded processes and maximize resource efficiency.

About the company

ISRA VISION PARSYTEC AG is the world's largest supplier of surface inspection systems in the metal industry: 18 of the top 20 steel manufacturers make use of ISRA products. With more than 540 installations around the globe, customers not only benefit from an advanced surface inspection system, but also receive reliable and comprehensive information about the relevant surface defects on all production levels. The innovative EXPERT5i software solutions allow the customer to prepare customized surface quality and yield management applications while integrating surface quality data with process data.