Manufacturing enterprises with factories in numerous locations today face the fundamental challenge of ensuring the same level of quality at all the sites and across the entire value chain. iTAC Software AG’s manufacturing execution system (MES) supports this crucial requirement in all manufacturing processes, from planning, through production to dispatch.

Multi-factory M2M communication

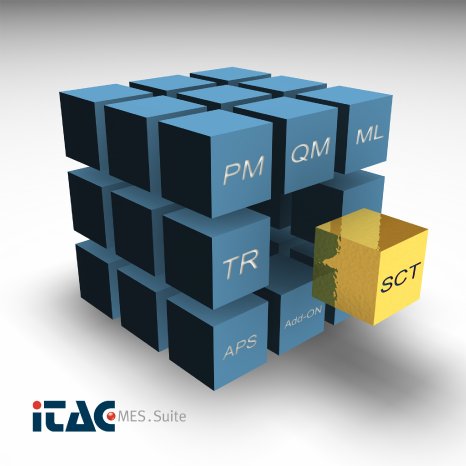

The iTAC.MES.Suite Supply Chain Traceability (SCT) Service facilitates communication beyond company and geographic boundaries. This standardized interface reflects the Industry 4.0 principle and enables machines to query the entire device history record of an unfinished product online. Intelligent networking and the digital product memory provide machines at different sites with production-related information.

Enterprise and roll-out capability

The iTAC.MES.Suite is roll-out capable for an effective deployment across numerous locations. In parallel, iTAC has developed a platform and manufacturer-independent framework called iTAC.ARTES (Advanced Reliable Technology for Enterprise Systems). This middleware provides the technological layer for state-of-the-art enterprise applications based on the Java EE platform. At the same time, it unites layer clustering with failover and load balancing mechanisms, plus a high-efficiency communication protocol and monitoring. iTAC.ARTES’ interfaces and services facilitate the transmission of complex data, the connection of function calls between the individual system components and the security of transactions, alongside associated high-availability.

As a result of this combination of technological features and other benefits, iTAC is absolutely unique in the international MES market. It provides its customers with the technological flexibility they need to implement large-scale IT infrastructure projects. Platform independence, standardized and downward-compatible interfaces and release capability guarantee its future viability and sustainability.