Visit us at Sensor + Test in Nuremberg, May 2012, 22nd -24th, booth # 565 in hall 12.

The optics which is built into infrared systems of metrology, test and monitoring equipment is required to transmit high-quality images and signals with long-time stability. It must do so despite harsh environmental conditions and process-induced impacts on optical components and their coatings. DLC - also referred to as "hard carbon" IR coatings - represent the state-of-the-art in optical systems of thermo-sensor-based monitoring plants for industrial, civil and military applications. They can be manufactured on such materials as silicon or germanium. This can be achieved, in the simplest case, through adaptation of refractive indexes (single-layer coating).

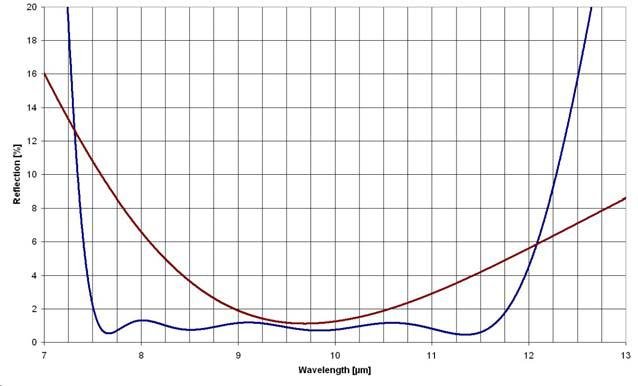

Jenoptik's newly developed Hybrid-DLC coating unites lasting resistance with the clearly improved transmittance of a dielectrical coating (Fig.1). This places Jenoptik among few companies worldwide which have the capability to selectively manufacture customized IR windows of highest durability and lowest residual spectral reflection. A sophisticated design and production process makes it possible to minimize internal coating tensions and, hence, warrant the durability and adhesive power in accordance with such established testing standards as TS 1888 (Windscreen-Wiper Test).

This successful product line will be extended by hybrid filter coatings in the future.

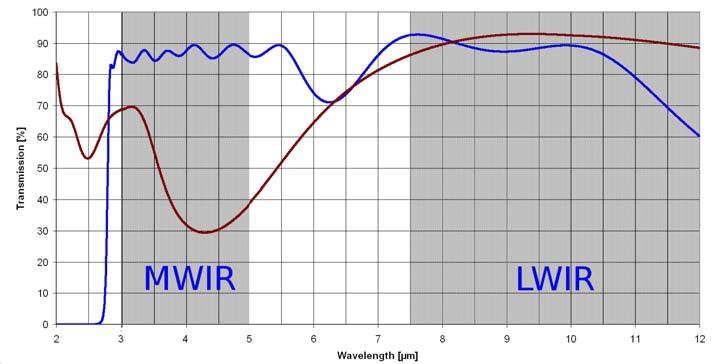

In addition, these spectral properties can be achieved in two separate wavelength ranges (e.g. MWIR and LWIR). Multispectral coatings of this type provide users of coatings with new solutions in design and application. By way of example, Fig. 2 shows a multispectral Hybrid-DLC coating with optimized transmittance (Avg > 80%) between 2.7 μm and 11 μm.