As announced during the awards ceremony in May 2014, the first place in the Innovation Award Laser Technology 2014 went to the Fraunhofer ISE for the innovation “Laser-fired Contact (LFC) Technology for the Production of Highly Efficient Silicon Solar Cells”. The award was presented by the German association Arbeitskreis Lasertechnik e.V. and the European Laser Institute, ELI, during the International Laser Technology Congress in Aachen (AKL).

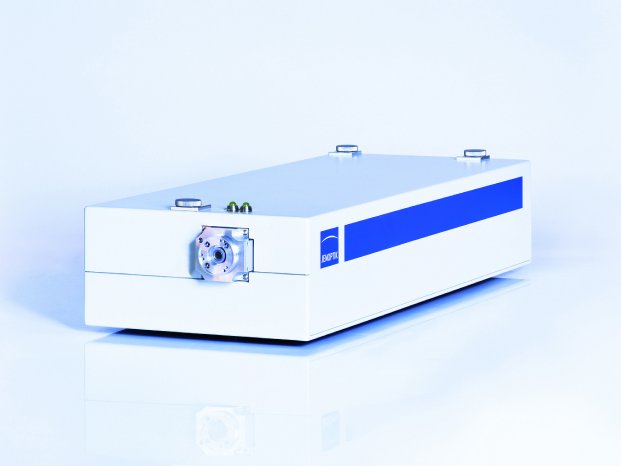

When developing this LFC technology for the laser-based rear side contacting of solar cells, the ISE used Jenoptik’s disk laser JenLas® disk IR70. With this laser, it is possible to make up to 25,000 contacts per second. Other fields of application for this laser in the photovoltaic industry are metal wrap through (MWT), emitter wrap through (EWT) and laser edge isolation (LEI).

The infrared disk laser is part of the JenLas® disk IR product line which enables the user to flexibly optimize process parameters. For example, the laser pulse length can be adjusted independently of repetition frequency and laser power. With a laser power of up to 65 W, a pulse energy of up to 7.0 mJ and repetition frequencies of up to 300 kHz, these lasers can be used for a wide range of applications.

In addition to their use in the photovoltaic industry, lasers of the type JenLas® disk IR are also perfectly suitable for machining hard and brittle materials such as diamond, silicon carbide or titanium alloys. Due to the high pulse energy, the laser can be used to remove and drill carbon fiber-reinforced plastics as well. Moreover, the disk technology makes the laser insensitive to back reflections and, thus, makes it the ideal tool for processing highly reflective materials such as copper or aluminum.

A picture can be found for download in Jenoptik’s image database/Lasers & Material Processing / Press.

Jena, June 2, 2014