Joloda Hydraroll has been a leading provider of loading and unloading solutions for over 60 years, delivering more than 500,000 systems worldwide. With an extensive range of equipment, Joloda Hydraroll can be relied upon by global suppliers for solutions from the aeroplane to the front door. The company is a one-stop shop for businesses’ loading and unloading requirements, with offices across four continents and a network of more than 30 distributors delivering local expertise.

New LoadMatic Lite Automated Loading System

Within some sectors and markets, such as the FMCG sector in Europe and America, trailers must travel exceptionally long distances from the manufacturing plant or distribution centre. In this scenario, it might not be possible to ensure a dock at both ends of the journey that is compatible with a trailer modified for automated loading and unloading. Alternatively, businesses might deliver directly to the customer warehouse or shops that choose to unload manually using forklifts.

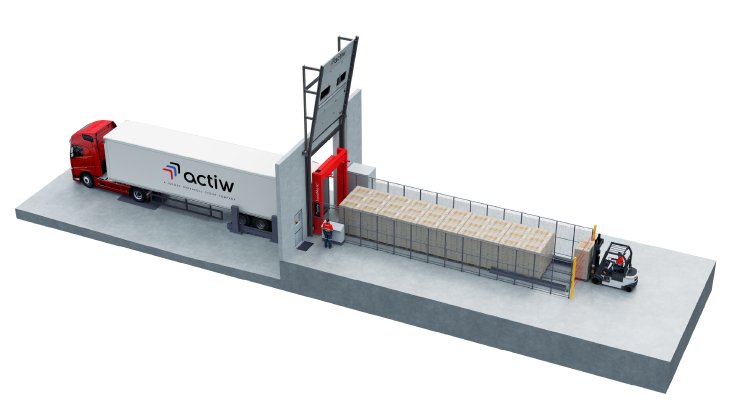

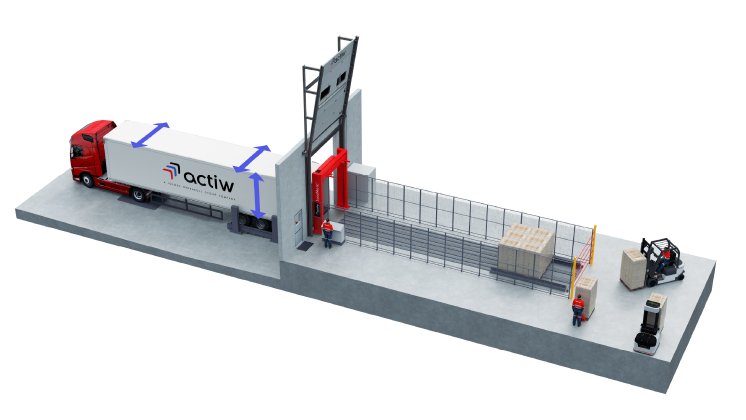

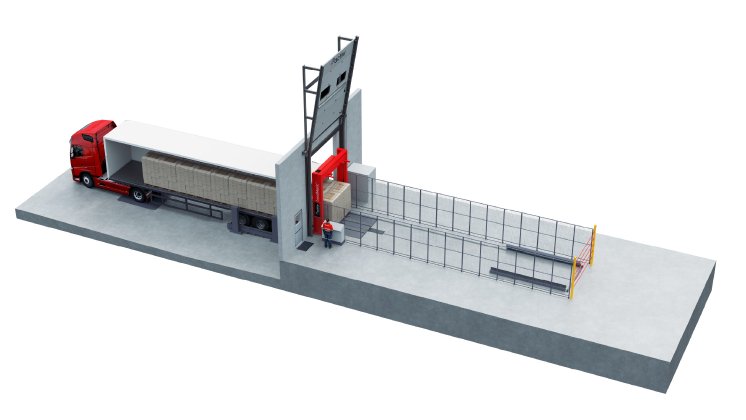

Joloda Hydraroll supports these businesses with unmodified trailer loading solutions that remove the need for dedicated trailer fleets. New to the range is the the LoadMatic Lite – a more versatile, entry-level variation of the Joloda LoadMatic system.

Capable of loading standard, non-modified trucks and trailers with up to 26 pallets in just six minutes, the system requires minimal dock modifications and integrates seamlessly into existing dock environments. It supports a wide range of pallet types and complex load patterns. Pallets are staged at the rear or side of the dock using forklifts, electric pallet stackers or AGVs, queued, then transported down the dock row-by-row before they are loaded into the trailer in one shot.

Wouter Satijn, Sales Director at Joloda Hydraroll, comments: “We are committed to helping more companies worldwide solve their specific loading and unloading challenges. LoadMatic Lite offers businesses a low-commitment, scalable solution to help reduce loading time and improve accuracy and consistency while preparing for future automation. It’s a smart investment for growing companies to stay competitive.”

Other unmodified trailer loading solutions include:

- The LoadMatic® – a fully automated end-of-line loading solution for regular, non-modified trucks and containers to transport either palletised or palletless industrial goods. The system can connect to the production line and can be specified with Joloda Hydraroll’s LoadForming and LoadBuffering solutions.

- LoadForming system – offers flexibility in loading patterns and pallet orientations, allowing for precise and consistent load positioning. It accommodates various pallet types, even within the same load, and supports double stacking for increased efficiency.

- LoadBuffering system – ensures the loading capacity for automatic loading and stabilises the upstream volume variations before loading and LoadForming. Provides more flexibility for loading operations if the truck order changes just before loading.

An Automated Trailer Loading System can improve operational efficiency for any business with a high volume of incoming or outgoing goods in their factory or warehouse, especially businesses where the flows are following fixed routes. This includes businesses that shuttle traffic between factory and warehouse or frequent deliveries to the same locations.

While it can take 30-45 minutes to load a full trailer using a forklift truck, an automated loading system can achieve this in as little as three minutes. Companies can move the same number of pallets each day, but with fewer people, trucks, and forklifts, leading to reduced operating costs, improved loading bay safety, a reduction in product damage, better utilsation of space, and a smaller carbon footprint.

Automated Trailer Loading Systems on display at LogiMAT 2025 will include:

- Moving Floor System – a heavy-duty, flexible slat conveyor belt system ideal for any business that needs to shuttle high volumes of abnormal pallets or unpalletised goods, such as whiskey barrels or tyres.

- Slipchain Pallet Loading System – a pneumatically activated rise and fall chain combined with a rollertrack system for trailer and dock. For businesses with a small fleet dedicated to shuttling a high volume of palletised goods.

- Trailerskate System – designed to automate loading for businesses with a larger fleet of trailers used for high-volume, medium to long shuttle hauls. Long skates are fitted to the floor to perform the loading and unloading, allowing businesses to retain a multifunctional trailer, with automated loading and unloading as required.

For businesses looking to speed up handling heavy or abnormal loads, such as paper reels, pallets, and air freight, Joloda Hydraroll loading solutions include:

- Skate & Track System

- Rollertrack System – a pneumatic rise and fall floor that can be built into trucks or trailer floors to help operators move loads quickly and easily.

- Modular Rollerbed System (MRS)

- MRS Powered Cargo Roller (PCR) – a new innovation for the air cargo industry. The PCR system from Joloda Hydraroll has a uniquely low profile of just 70mm, making it possible to fit the Modular Rollerbed System with Powered Cargo Rollers into any standard model for the first time. As a result, it is now far quicker and more cost-effective for air cargo businesses to deploy a PCR trailer, as they no longer need to rely on specialised trailer designs.

Joloda Hydraroll designs, manufactures, installs, and services a complete range of equipment for air cargo handling operations, both airside and landside. Companies can benefit from an extensive portfolio of trailer, warehouse, and conveyor solutions for loading and unloading air cargo, as well as servicing and maintenance, from a single provider.