“Depicting machinery in 3D helps customers to pinpoint any geometric interference during the early offer phase. This improves planning security, as any spatial conflicts in the production shop are recognized and corrected right from the start,” says Patrick Bürger, head of Plant Design at KHS. Unnecessary loops in the planning process – and consequently additional costs – are thus avoided early on. “We show customers how the line or machine fits into their existing environment. If required, we include the operators in the advance planning process and show them how they can later move around between the machines. Their feedback is of great value to us and enables us to devise an optimum layout,” he continues.

3D planning also shows machine heights

New software is used to this effect that speeds up the entire 3D planning process as it is easy to use. At the same time the system depicts the relevant machines and conveyor elements in greater detail than in the previous 2D variants. This means that production environments spread out across several floors or located in extremely confined spaces can be simply and clearly visualized. 3D line design can be applied to all machines in the KHS portfolio – regardless of the container or beverage segment.

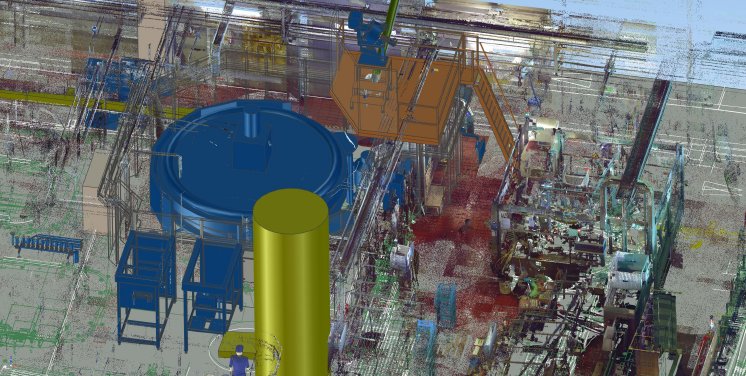

To further improve planning security KHS offers laser scans that can be easily integrated using the new software. Here, a 360° camera set up on a tripod creates a realistic, practically consistent photographic image of the relevant production environment. “These individual images are then superimposed. This creates what’s known as a scatterplot that takes all geometries into account. Interferences and disruptive elements are reliably detected,” Bürger explains. This is particularly advantageous when integrating new systems into parts of buildings that already contain machinery as it prevents possible collisions with existing equipment.

3D models for further processes

Moreover, the use of 3D models is also helpful to further processes. According to Bürger, customers are increasingly requesting rendered images for system visualization so that they can display and process live data from their MES on a production monitor. “This enables plant operators to track what’s happening where on the line in real time and to see how high the current output is, for instance. We can provide these images as an option,” states Bürger. 3D data can also be used for the purpose of building information modeling (BIM). This describes a networked planning method in which all assets – from data on the building through piping and ventilation systems to the energy supply and ultimately the filling line – can be compiled and displayed in a single line design model. “We have quite a bit of experience with BIM projects. We’ve had plenty of very positive response regarding the data quality here, for example. Our optional support program not only includes the provision of this data in various exchange formats but also enables plant operators to take part in regular BIM coordination meetings,” Bürger adds.

Another advance 3D planning option is to use mobile VR goggles. Bürger claims that this is particularly beneficial in confined spaces as it shows where and how operators can move from machine to machine. “VR simulation helps to provide simpler access to complex areas and to clearly visualize these. We’re hoping to find a number of prototype customers by the end of the year who we can test this form of visualization with in specific offer planning processes and present the benefits on the ‘live’ object.”

In Bürger’s opinion, 3D line design by KHS is currently setting standards on the market. “We’re moving into the future together with our customers. The feedback we’ve had so far has been extremely positive.”