"For food and beverage producers the container is a composite part of their marketing strategy. For us it's the heart of the system," says Frank Haesendonckx, head of Sales and Technology at KHS Corpoplast in Hamburg, Germany. New bottle formats, marketing concerns and cost pressures demand shorter intervals for format changeovers on filling lines. KHS gives its customers extra support here with its comprehensive packaging consultancy service, adopting a holistic view of the line, selecting the right preforms and bottles and providing much faster format conversions. The supply of conversion components can be reduced to eight weeks maximum. This enables bottlers to implement new launches faster and introduce new containers and packs to market more quickly.

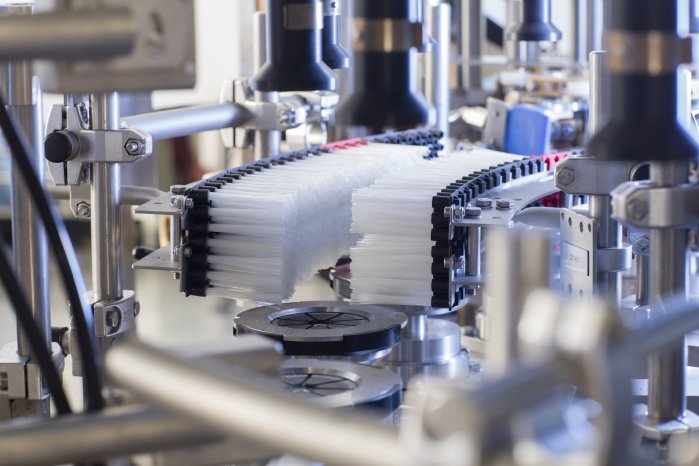

Faster processing is not the only benefit, however. The integrated, holistic packaging systems supplied by KHS not only concentrate on the packaging design but also on the standardization of procurement processes and components, predictive warehousing and, as a result, faster availability of spare parts. To this end the company has provided its own resources and further optimized its warehousing and logistics processes. "We can offer first-class consultancy and support across all topics and machines which take into account every single aspect, such as container design and production, filling, labeling and packaging," says Haesendonckx. This not only applies to new machines but especially also for existing lines which are upgraded by and retrofitted with conversions.

Attractive and efficient bottle design

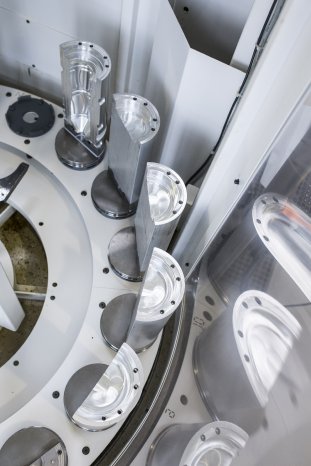

A new bottle shape is often the reason for a format conversion. In order that the new design meets the specifications and requirements of the customer, the Bottles & Shapes™ program develops bottles which are distinguished by two main characteristics: an attractive design for consumers and a high level of efficiency on the filling line. "The earlier we start to develop projects together with our customers, the better we can influence the design of their containers," says Armin Wille, product manager of Conversions at KHS. The lightest bottle is of no use to the customer if pallets are later unstable or the output capacity drops. It is thus important to see the big picture and include all sub-functions in the project from the beginning. To ensure an optimum quality of design and engineering KHS has strengthened cooperation throughout its production sites in Design Engineering, Production, Offer and Order Processing and Logistics.