The FluidMaster system closes a gap in the field of closed, non-removable heat transfer systems. Kipp Umwelttechnik can now offer devices and systems for the cleaning of all heat transfer systems. Together with its sister company mycon, Kipp Umwelttechnik focuses on automation or partial automation as far as possible and economical. FluidMaster is also equipped with a PLC. The suitable cleaning program can be easily selected and started.

The system has several sensors that indicate the development of pressure and volume flow as well as the temperature and pH value of the cleaning medium. FluidMaster is constantly monitored for tightness of all connections within the system and switches itself off automatically in the event of an unexpected flow (e.g. leakage).

All recorded values are constantly recorded and stored per second or minute, depending on the setting. The course of the cleaning is thus completely visible and can be documented at any time during or after the cleaning in any desired form. FluidMaster can therefore also remain in operation for longer periods without personnel monitoring onsite.

FluidMaster works with relatively high flow velocities. For large-volume heat transfer systems, the mycon SpeedMaster system can also be used as a combination device. SpeedMaster increases the flow rate of the cleaning medium and can also introduce a second cleaning medium at the same time if required.

For cleaning smaller heat transfer systems, the Mini-FluidMaster is also available as a lightweight cleaning device.

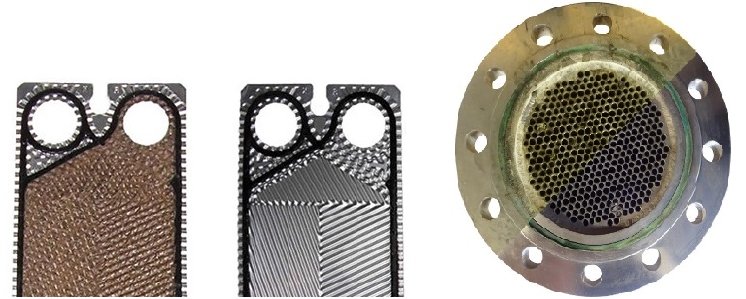

Images: mycon GmbH / Kipp Umwelttechnik GmbH