In addition to inner tube cleaning, TubeMaster can polish the inner tube surfaces. This provides improved flow and temperature exchange. Experience has shown that cleaning intervals can be significantly reduced. Kipp Umwelttechnik cleans / polishes the inner side of tubes made of almost all materials using TubeMaster system. TubeMaster cleans without water and is therefore very well suited for the cleaning of shell and tube heat exchangers in desulphurization plants for gas or oil. Kipp Umwelttechnik has experience in cleaning pipes from almost all materials.

A special case is the cleaning of tube bundle heat exchangers made of graphite. Cleaning with high pressure water is rarely effective here, since the pipes cannot withstand higher pressure. However, the deposits on the inner tube surfaces to be removed are often significantly harder than the tube material, a high pressure water cleaning with pressures of 20 to 50 bar is usually not sufficient for cleaning.

The incrustations must be removed without damaging or roughening the inner pipe surfaces. Kipp Umwelttechnik uses the TubeMaster system from its sister company mycon for this work area. For the cleaning of graphite heat exchangers, specially developed nozzles and special abrasives are used. For the removal of viscous residues, Kipp Umwelttechnik relies on cryogenic soft abrasives. This increases the polishing effect on the inner walls of the pipes.

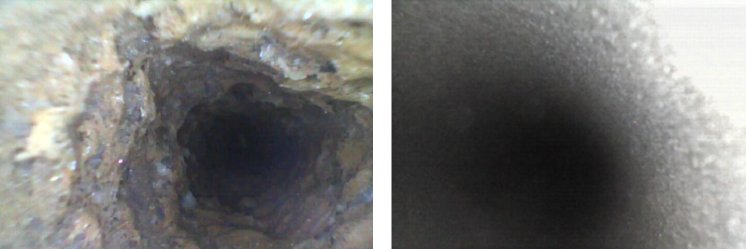

The incrustations are removed layer by layer down to the pipe material. The surface quality of the inner tube walls is further improved. A lot of experience and a high qualification of the employees is required in this field of work. In order to avoid damage, the cleaning work is constantly checked using an endoscope or pipeline camera.

The Hamburg Borsigstraße waste incineration plant commissioned Kipp Umwelttechnik with the cleaning of three graphite tube bundle heat exchangers. The work was successfully completed within four working days without any damage to the pipes. The exchangers were then immediately put back into operation.

From the interview with Mrs. Dipl.-Ing. Bürkle/ MVB:

"Kipp Umwelttechnik had already successfully cleaned a graphite heat exchanger with a cryogenic soft blasting media at our company site in 2003. Kipp Umwelttechnik has now cleaned three exchangers of different sizes for the first time in our company. The inner diameters of the pipes are 37 mm and 25 mm respectively. The hard deposits in the exchangers had different thicknesses, from approx. 1 mm to thicker incrustations over almost the entire cross-sectional area. Kipp Umwelttechnik was able to clean all exchangers completely and without damage, and the surface quality of the inner tubes was improved after cleaning. The cleaning was carried out professionally using a closed system including exhaust air cleaning.

Despite the demanding spatial conditions, the cleaning was completed within the specified time."