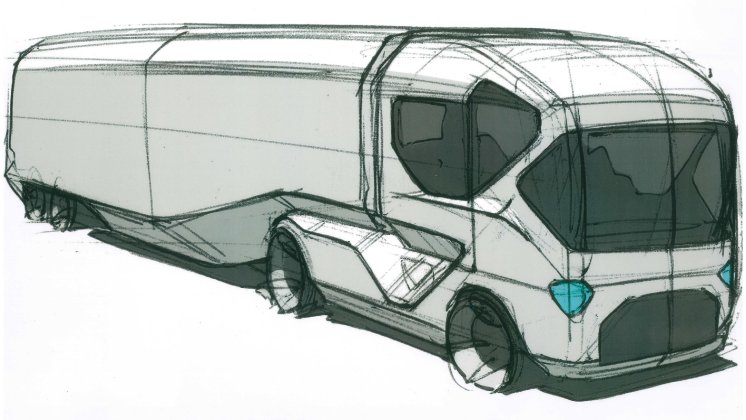

Building on the experience acquired in the production of more than 32 million truck and trailer disc brakes worldwide, Knorr-Bremse's development engineers are currently working on a new brake generation called Synact - the name derives from a combination of synergy and actuation. The design of the mechanical parts is such that clearance is reliably kept within a narrow tolerance band, while the internal mechanics are very smooth-running and ideally geared. The caliper is lighter but at the same time stronger and ensures that a braking torque of 30 KN can be maintained even during prolonged braking maneuvers.

Knorr-Bremse has thereby laid the foundations for very good responsiveness and enhanced braking torque regulation. Combined with an approach that offers a complete, functionally optimized wheelend including friction pairing and actuator, Synact sets the standards for the vehicle generations of the future as well as paving the way for the automation steps to be expected in the coming years, such as platooning. Synact lays the foundations for a complete modular system that will enable the brakes to be equipped with various functionalities in line with customer requirements. In addition, Synact clears the way for further advances in terms of automated driving.

Customer benefits for vehicle operators and manufacturers

Along with advantages in active safety, Synact offers tangible customer benefits including longer service life, lower weight and easier maintenance. Synact also provides the basis for the advanced future connectivity of mechanical and electronic brake components. As well as replacing purely mechanical functions with mechatronic ones, the developers at Knorr- Bremse are planning to provide sensor-based condition monitoring for the entire wheelend.

More braking torque, less weight

Thanks to the optimized design of the caliper and backing plate and the ingenious structure of the internal mechanics, Synact enters a new dimension in terms of power-to-weight ratio. Braking torque has been increased by eleven percent and at the same time weight has been reduced by some ten percent. Further benefits are generated in conjunction with the complete wheelend - brake, disc, pad and actuators - through the use of the optimized flat SD disc, for example. Compared to conventional disc designs, this not only saves additional weight - thanks to their special design, these discs also show less deformation at extreme temperatures, develop fewer heat cracks and ensure more even use of the friction mass, making for optimum wear and thus an even longer service life.