The bypass valve prevents unnecessary braking of the turbocharger with sudden closing of the throttle valve, so clearly reducing the turbo lag effect.

Compared with existing pneumatic solutions the electric bypass valve is more compact, efficient and cost-effective: There is no need for pneumatic lines, a vacuum tank, non-return valve or electric air switching valve. Direct actuation cuts switching times by as much as 70%, something that particularly caters for sporty turbo engines with fast load alternation.

Bypass valves are often also known as pop-off or blow-off valves.

Function

If the accelerator is suddenly released at a high turbocharger speed, causing the throttle valve to close, the high back pressure produced behind the compressor will not be able to escape. This has a strong braking effect on the compressor wheel, exposing the closed throttle valve and turbine side of the turbocharger to great loads.

When the throttle valve opens again, the turbocharger first has to be brought back up to speed. This effect is known as turbo lag, i.e. a fall-off in performance when accelerating after overrun operation. The bypass valve will prevent this.

It releases a bypass to the suction side in overrun, so ensuring a fast drop in pressure on the compressor side. This means that the braking effect on the compressor is not as strong. When the driver accelerates again, i.e. by opening the throttle valve, the bypass valve closes, and full charge pressure is again immediately available.

This reduces turbo lag, which is now barely noticeable.

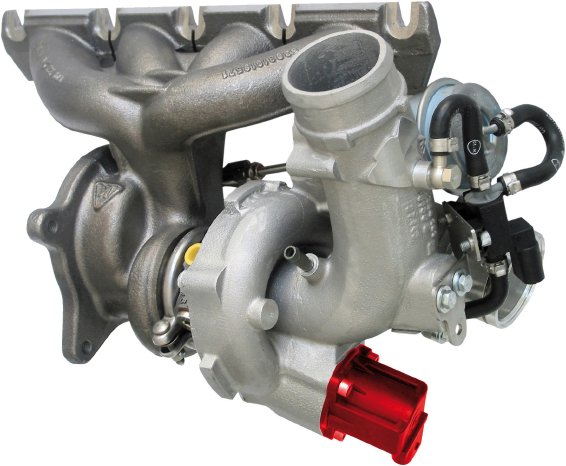

Pierburg has incorporated the electrically operated bypass valve in the turbocharger design, so creating a highly complex component for new generations of engines.