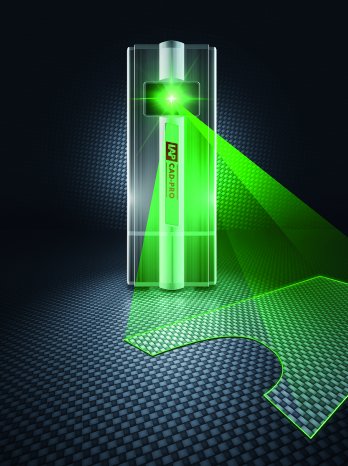

Even at large distances, high-precision CAD-PRO laser projectors enable true-to-size display of laser outlines on 3D objects. Laser lines are generated based upon existing CAD design data. Objects may be precisely aligned and positioned. This is much faster, more flexible and reliable than using physical templates or measurement techniques.

For higher reliability during manufacturing, LAP has expanded its successful product family of CAD-PRO laser projectors to include new models with a green laser diode: The CAD-PRO LD green has a laser source with a service life of up to 30,000 hours - three times the service life of conventional DPSS laser modules. In addition, the unit features optimal visibility of the projected laser lines especially on dark surfaces.

The package is complemented by the user-friendly LAP PRO-SOFT software. The software manages, visualizes and documents the projection steps and can be simply and intuitively operated via keyboard, tablet PC or remote control. For large objects like rotor blades, the multitasking version PRO-SOFT MT allows several teams to work simultaneously on the same tool. Furthermore, the software supports a variety of CAD file formats as well as the direct export of LAP laser projection data from leading composite programs. The easy import and export of data without additional conversion help users to save valuable time and costs.

„LAP COMPOSITE PRO allows for a consistent workflow from design to industrial production. The solution supports companies worldwide to make their layup processes faster, simpler and more cost-effective, and to ensure the high quality of their products“, explains Ralf Müller-Polyzou, head of marketing and product management at LAP GmbH.

Live demo: Laser projection for production of WEC rotor blades

At Composites Europe, laser specialist LAP (booth 8b/G02) will show in a live demo how the production process may benefit from laser technology by saving time and resources. Companies may improve process reliability, increase accuracy and optimize throughput. Demonstrated on a rotor blade half shell you will see how projection data from CAD files is imported, how calibration enables true-to-size display of laser outlines and how objects may be precisely aligned and positioned without physical templates or measurement tools.