With its measurement system called “Airfield Luggage Detection” (LaseALD), LASE PeCo has installed a product which fulfills the specific requirements and conditions of the Cologne Bonn Airport. This airport is one the biggest German hubs in the field of freight traffic and especially here, a laser-based object detection on the landing fields is necessary due to the existing ban on night flights. Thus a highly precise and reliable detection of objects in the crossroads area of the landing fields is ensued.

Particularly on this site in Cologne-Bonn detours shall be avoided as well as a time saving of approx. 15 minutes can be achieved. Previously each vehicle had to give a wide berth to the airfield. For example one logistics provider carries perishable food to the maneuvering area in order to supply the airplanes. Initially the construction of a bridge or tunnel was planned as an alternative, but wasn’t feasible due to complex structural measures. This is why the application LaseALD proves itself as ideal solution after extensive tests.

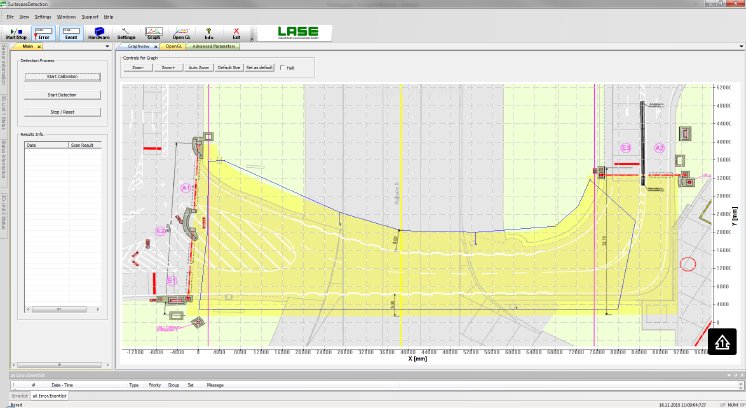

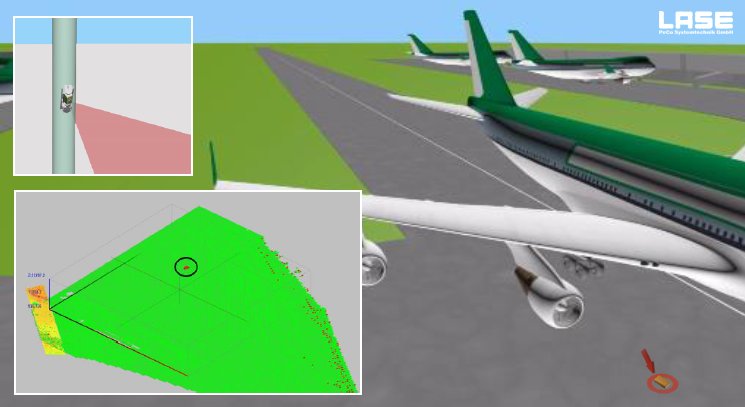

At Cologne Bonn Airport this laser-based application shall ensure a reliable detection of fallen items of luggage with minimum dimensions of 50 cm x 40 cm x 20 cm, which derive from the trolley after passing the crossroads area. Thus damages at the airplane engines by these objects can be avoided. Before two installed boom gates close, the crossroads area is checked for foreign objects by two 3D laser scanners. After it the operator receives a message on his display. In case of an object detection an alarm will be given immediately, whereby the detected objects are shown within the LASE-Software three-dimensionally.

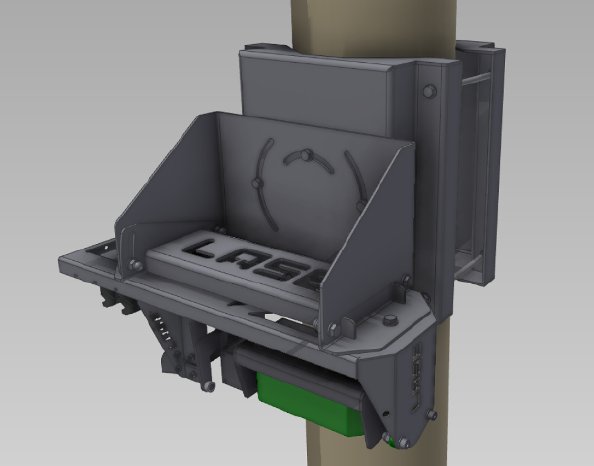

The application is an overall system of different hardware components, which consists of a 3D laser scanner, CAN/Ethernet converter, industrial-PC, digital I/O-Module and a display for status information. Point of installation of the 3D laser scanners is a pylon construction near the runway boundary. It’s sheltered through weather protection housing against general weather conditions and has an individual angle setting of +/- 45°. The 3D laser scanner has a scan range of up to 80 m and by its high scan frequency of 20/40 Hz it detects objects reliably. The application software uses special algorithms to detect the objects on the airfield, whereby static objects like signs or boundaries are filtered out. The final status of the open space examination will be displayed on a separate monitor.

By the use of highly precise laser technology an extensive airfield monitoring can be operated, which ensures reliable object detection even at darkness or inclement weather. High system flexibility also allows an application to individual requirements and conditions.