For almost 30 years now the company has manufactured laser optics with hard dielectric coatings. The technical know-how has been transferred in the past few years to the coating of optical fiber end surfaces and been made available for entry into the market.

After assembly, the fibers are coated using physical vapor deposition, PVD, to achieve high damage thresholds. Due to this fast coating method and flexible capacities, these coatings are surprisingly inexpensive.

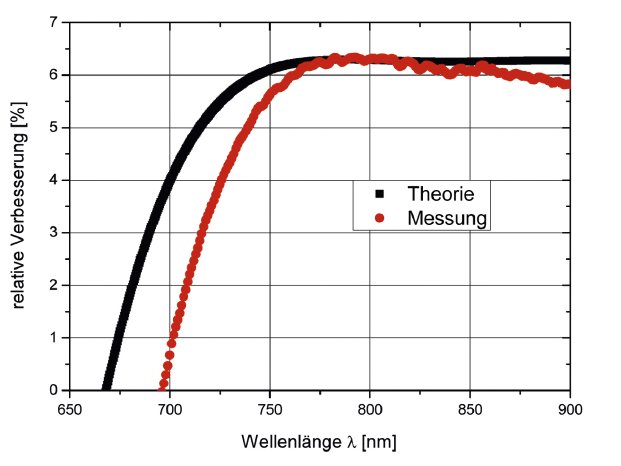

Anti-reflection (AR) coatings are available for one, two, or three wavelengths. The so-called single AR coating is used for one wavelength (e.g. 808 nm), the dual AR coating for two wavelengths (e.g. 808 nm + 980 nm), and the broadband AR is a coating for a wide wavelength range (e.g. 460 nm - 700 nm).

More Information

http://www.lasercomponents.com/...

Trade Shows

- Security + Defence, Sept., 24 - 25, 2013, Internat. Congress Center Dresden, Germany, Booth 304

- enova - OPTO, Oct., 08.-10., 2013, Paris Porte de Versailles, France, Booth L9

- PHOTONEX 2013, Oct., 16.-17., 2013, Ricoh Arena, Coventry, UK, Booth D20

- BiOS EXPO 2014, Feb., 01.-02., 2014, The Moscone Center, San Francisco, USA, Booth 8517

- Photonics West 2014, Feb., 04.-06., 2014, The Moscone Center, San Francisco, USA, Booth 517