The manufacture of polarization-independent beam splitters is a complex process in which the coating process must be carefully monitored. Usually, the coatings are deposited in an ion-assisted deposition (IAD) or ion beam sputtering (IBS) system. This produces coatings with a very high packing density, which in turn allows the optics to retain their properties even in a vacuum or under severe temperature fluctuations.

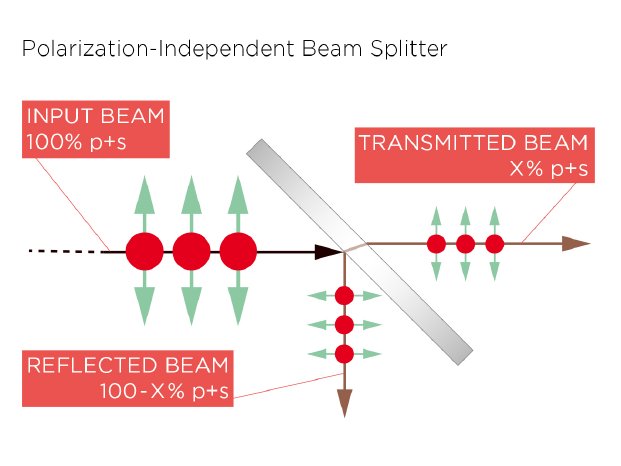

The real-time monitoring of laser power is used in applications that require permanently stable performance. If irregularities are detected, the pump power can be adjusted to compensate for them. The measurement is performed on a decoupled part of the laser beam. Even slight irregularities in the polarization of the laser would falsify the measurement results of a polarizing beam splitter.

Further product information:

Partially Reflective Coating