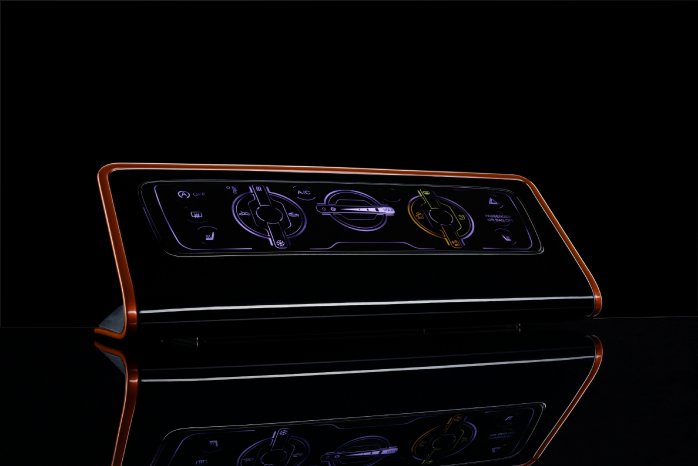

Transparent, conductive, flexible – touch sensors for every requirement

For its HMI solutions, Kurz employs touch sensors with the name PolyTC from Kurz subsidiary PolyIC. The sensors comprise silver-based metallic grid structures on a PET carrier. Being highly conductive, transparent and translucent, they are suitable for a wide range of applications, whether it be control panels that appear opaque in daylight but can be backlit, high-resolution touchscreens, or sensor activated ambient lighting in unadulterated colors. A further advantage of these sensors applicable to the automotive sector is their mechanical flexibility. Organically curved shapes are the latest trend in car interiors. The elastic PolyTC sensors can be integrated into fashionable, curved components.

The most cost-effective sensor integration for every application

PolyTC sensors are manufactured in a fast roll-to-roll process and can be reliably supplied in large quantities. They can be integrated into plastic components by means of a number of different processes, including in the conventional manner using PSA (Pressure Sensitive Adhesive) or OCA (Optical Clear Adhesive) bonding. They can also be integrated during the injection molding process using the IML (In-Mold Labelling) process, with simultaneous IMD coating of the component surface if desired. Furthermore, Kurz has developed a Functional Foil Bonding (FFB) process based on hot stamping technology along with an associated integration machine. Sensors integrated using the FFB process exhibit perfect adhesion to the substrate in alternating climate tests – in many cases a process advantage over PSA and OCA bonding.

Thanks to the diverse range of processes available, the foil bonding can be performed manually, semi-automatically or largely fully automatically for cost-effective sensor integration that can be tailored to the specific project requirements. Kurz determines the most efficient integration method for every project based on customer specifications, component geometry and sensor requirements.

Integrated surface protection and reliable readability

Surfaces in car interiors need to fulfill highly stringent requirements. Kurz has developed top coats that exhibit high resistance against a wide variety of external influences, for example abrasion, scratching, chemicals, and UV radiation. These meet the demanding specifications of the automotive industry. Furthermore, the seamless surfaces with no knobs or buttons are soiling-resistant and easy to clean.

Coatings that have also been tailored to the specific requirements of HMI surfaces will be on display at the Kurz booth. These novel coatings ensure easy, distortion-free readability of control panels and displays from various viewing angles and under different incident light conditions. The coatings can be produced according to customer-specific requirements: for high-gloss displays with exceptional color brilliance and a contrast-rich image, or for matte anti-glare or even completely antireflective screens.

High-end designs for automotive interiors

Besides sensor and integration technology for HMI concepts, Kurz will also be presenting a wide range of new surface designs at the trade fair. This includes IMD designs with special haptic effects, partial and full-surface backlit designs, along with silk screen printed designs with a special depth effect from Kurz subsidiary Burg Design. The coating technologies employed allow fast and easy design changeovers, thereby economically catering to the trend for individualization in car interiors. To find out more, visit the Kurz booth A7020 in Hall 7.