Wallbox design for the vehicle of tomorrow

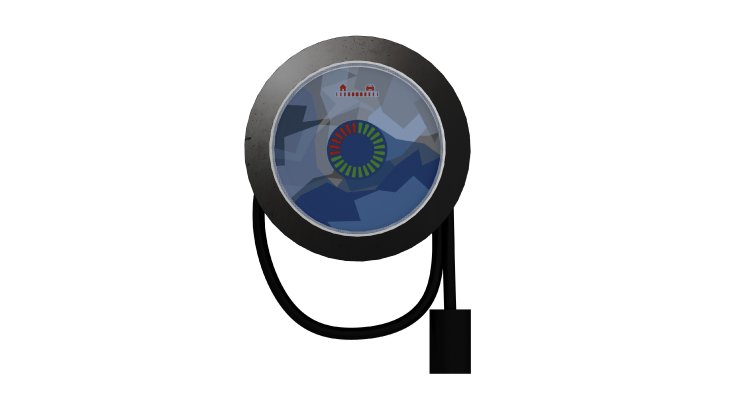

Together with the international material producer Covestro and the manufacturer of injection molding machines Sumitomo (SHI) Demag, KURZ has developed an innovative concept for an e-nozzle - known as a wallbox. What’s special about it is that it is where design, functionality, and sustainable production come together. The wallbox is not only equipped with a display, but also with touch operation and backlighting - a real eye-catcher! “We see more and more electric cars on German roads - which means that the wallbox is also becoming part of our everyday life,” explains Martin Hahn, Head of Application, Technology & Innovation in LEONHARD KURZ’s Business Area Plastic Decoration. “As a result, the demands on wallbox design features are increasing too. The wallbox of tomorrow will become a functional design element - both visually appealing and smart to operate. It should also be made efficiently and resource-conserving in respect of sustainability.”

Live demonstration during K 2022

At K2022, KURZ and its respective partners will show how this can be achieved - with a live demonstration of production with In-Mold Decoration (IMD) at the Sumitomo (SHI) Demag stand (Stand D22, Hall 15). “Here, visitors will not only experience the sustainable decoration process up close, but also our all-electric injection molding machine IntElect2,220/660–1100, which is precisely tailored to the IMD application and enables particularly energy-efficient production and finishing of the wallbox,” explains Rustam Aliyev, Director Business Development Automotive & Electronic at Sumitomo (SHI) Demag, and adds: “The injection molding process and the decoration process are combined in a single, highly efficient step. This not only saves time and costs, but also leads to a reduction in CO2 emissions.”

Sustainable through and through

The raw materials provided by Covestro as part of the joint project also have a positive effect on the CO2 balance. In addition to high-quality materials, the KURZ partner also contributes its expertise and is actively involved in the development of the demonstration device: “We use our Makrolon® RE from allocated mass-balanced biowaste and residues as well as thermoplastic Makrofol® polycarbonate films for the wallbox,” explains Dr. Niklas Meine, responsible person for Marketing of Electrical Engineering and Electronics EMEA at Covestro. “Makrolon® RE has a very small carbon footprint and offers the necessary technical properties for charging stations, so that CO2 emissions can already be saved during the production of the wallbox. Last but not least, the wallbox is particularly durable and can be recycled thanks to its special material properties.” As a pioneer in the field of sustainability, KURZ also contributes the Group’s many years of experience. “Thanks to thin-film technology, our decorations don’t affect the recyclability of the components and are finished directly during production in the same step with the highly efficient, resource-saving IMD process,” explains KURZ expert Martin Hahn. “Unlike varnishing, no wet paint contamination or post-drying energy are an issue here.”

Digital showcase illustrates design diversity

The mobility of the future sees sustainability hand in hand with impressive design. LEONHARD KURZ and Covestro have managed to combine both aspects. In addition to the IMD live production demonstration at the Sumitomo (SHI) Demag stand, KURZ will be presenting a demonstrating device, as well as the use of decoration technologies and their special effects at its own stand (Stand A19, Hall 5). The wallbox design demonstrator and other material solutions for the electromobility, design, and electrification segments will also be on display at the Covestro Stand (Stand A75, Hall 6) - and a presentation on the cooperation and development of the demonstration device will take place here on October 20 at 11:00 AM. KURZ and Covestro also offer visitors the opportunity to experience the design diversity up close using the augmented reality app.

At a glance

K 2022 from October 19-26, 2022

LEONHARD KURZ Stiftung & Co. KG: Hall 5, Stand A19

Sumitomo (SHI) Demag: Hall 15, Stand D22

Covestro Deutschland AG: Hall 6, Stand A75

Product group: Machines and equipment for finishing, decorating, printing, and marking

Focal points of the LEONHARD KURZ trade fair appearance: Automotive interior/exterior, consumer electronics, home appliances, sustainability