“We are very pleased to be able to once again present numerous highlights to the public for the first time on the occasion of the K trade fair’s 70th anniversary,” emphasizes Rainer Süßmann, Head of Business Area Plastic Decoration at LEONHARD KURZ. “Our trade fair presentation will again make it possible for visitors to experience our comprehensive expertise in sustainable and forward-looking surface solutions. At our stand and at numerous partner stands, we will be exhibiting a wide range of exhibits, some of which have won awards. We will produce or finish selected products in live demonstrations directly on site. In addition, we attach great importance to sustainability and prove that high-quality surface finishes and sustainable production methods are no longer mutually exclusive.”

Here are some of the highlights from the different areas:

Automotive exterior design: Focus on current megatrends

In the automotive exterior segment, KURZ will present pioneering surface solutions that are strongly geared towards defining trends such as e-mobility and autonomous driving. The absolute highlight of the trade fair is the live production of a rear-end cover at KURZ Stand A19 in Hall 5. The efficient, series-ready technology enables the component to be realized with a seamless, closed surface - despite the component size (width: 852 mm). 2K material mixes and high-end Spinstack technology also enable targeted light barriers and structures for 3D lighting effects. Although two different plastics are used, the components can be recycled later on thanks to the carefully selected materials. In addition, KURZ uses an e-charging station with a smart touch function to demonstrate the wide range of variants in the design and manufacture of intelligently designed charging technology. The front panel of the innovative Wallbox with partial lighting and optional integration of sensors and display will be produced live using the IMD process at Sumitomo (SHI) Demag’s partner stand (Hall 15, Stand D22). There will be an augmented reality demonstration to showcase the design variety at the KURZ stand.

Components for the autonomous vehicle of the future are radar-compatible as well as 5G and touch-capable. At K 2022, KURZ will be presenting an exterior component in the form of an automotive design badge that can be color-matched according to customer specifications and, with indium metallization, also enables effective surface finishings with outstanding suitability for backlighting. KURZ thus offers a range of designs and functions that are virtually limitless. The IMD process used here is also economical and environmentally friendly, as the injection molding process and the decoration process are combined in a single, highly efficient work step. Last but not least, recycled materials can be used.

New decoration options for the vehicle interior

KURZ uses various demonstrating devices to show impressive light designs developed in cooperation with MENTOR, the renowned manufacturer of light guide systems. Thanks to a proven RGB algorithm, company-specific corporate identity colors can be implemented with full color fidelity. Light and surface design merge to create an innovative, futuristic design with fantastic effects and a high degree of customization. Unlike conventional processes, the light can be directed, distributed, and, in the right places, decoupled in the desired form, color, and brightness.

The Smart Crystal Panel, which was developed in cooperation with Swarovski Mobility and KURZ subsidiaries BURG DESIGN and PolyIC, not only visually enhances the interior of vehicles in the luxury segment, but also offers smart functionality for intuitive operation. The HMI (Human-Machine Interface) panel won the ABC Award in 2022 and impressively combines design and decoration, highly transparent sensor technology, and high-quality touch-capable crystals from Swarovski.

At K 2022, KURZ will also present an innovative development that enables new metallization designs with different color variations, color gradients, and even 3D geometries. The process is based on the reaction of two different metals with each other, is suitable for different processes, and can be used for Shy Tech designs. The new solution can be backlit and additionally enhanced with haptic and matte gloss effects. KURZ BIOFENSE® can also be used to provide the surfaces with long-term hygiene protection.

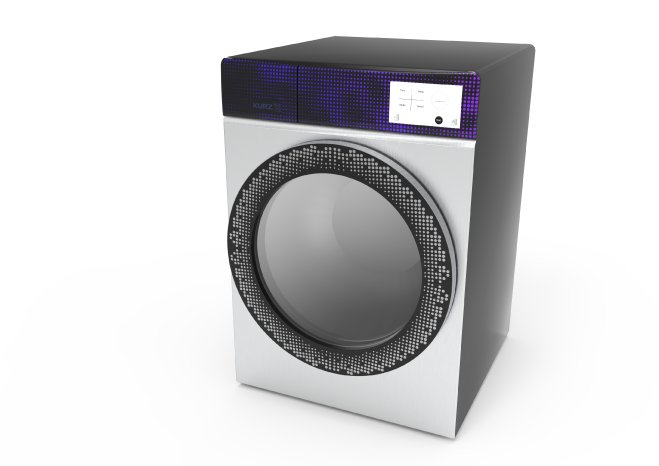

Home appliances: Merging design and functionality

KURZ’s innovative processes and complete solutions make it clear that the same, boring gray and white shades of household appliances are a thing of the past. KURZ presents illustrative examples in the form of various washing machine components, which enable a high degree of customization as well as the integration of backlighting and touch functions. The washing machine panel on display at the KURZ stand, for example, has a highly efficient human-machine interface, in which all possibilities for customization and transparency have been realized in a single component using IMD technology and In-Mold Electronics (IME). The great design freedom will also be evident at K 2022 in the form of various washing machine door designs with metallization. KURZ finishing enables multifaceted effects with high recognition value and can be implemented partially or over full surfaces. Customization via IMD UNIFY and integration of touch sensors via Functional Foil Bonding (FFB) will be demonstrated live on site in a combined process on a BINSPIRE machine from BAIER.

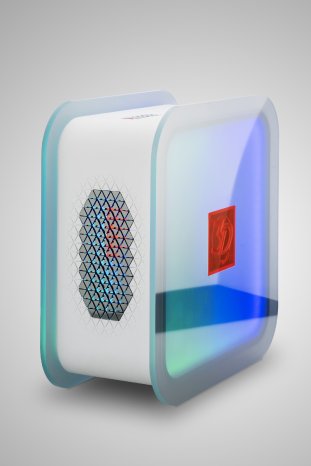

Sustainable designs for consumer electronics

In the field of consumer electronics, end consumers are increasingly placing value on environmentally friendly concepts that save energy and resources. KURZ helps manufacturers meet this requirement. The sustainable IMD and IME processes are also used in consumer electronics. Using various design-driven controller prototypes, the trade fair will demonstrate how recyclates can be decorated in a high-quality and appealing way so that it is in no way inferior to new material. Even backlighting and various lighting effects are easily possible, as is the use of partial metallization as a sustainable alternative to electroplating. KURZ product designs thus provide inspiration for the consumer electronics of tomorrow. Three design concepts will be presented at the KURZ stand: GAMING, LIVING, and FUTURE.

Innovative strength for the Health & Beauty segment

With the new LIGHT LINE® inVISIBLE, KURZ presents a diffractive transfer product that is a real eye-catcher, especially on cosmetics packaging. Thanks to the semi-transparent design, the finishing takes the appearance of transparent substrates to a new level by achieving a perfect interplay of colors and novel visual effects. The variety of colors also plays a major role with LIGHT LINE® inVISIBLE. Among other things, customers can choose from the exclusive trend colors used by KURZ - or they can opt for individual color matching.

The new ISIMAT I-Series machine from KURZ subsidiary ISIMAT is suitable for tubes, glass, and aluminum items, and its extensive functionality will be demonstrated to trade fair visitors. In addition to the entire range of printing and finishing techniques that the I-Series can cover with up to eight different modular printing stations, conical containers can now also be perfectly decorated. This groundbreaking further development is one of the most important features that KURZ and ISIMAT offer customers from the cosmetics industry. In addition to individual I-Series modules, the finished products can also be admired at the trade fair stand.

Sustainability solutions at the VDMA Circular Economy Forum

How can circularity work in the plastics industry? The Circular Economy Forum of the VDMA (Verband Deutscher Maschinen- und Anlagenbau e. V.) answers this question in the open-air area of Messe Düsseldorf. In a total of ten pavilions, VDMA members present their projects and technologies that enable the recycling of plastics. KURZ is also among the participating companies. At Stand P10, the thin-film specialist will be using the RECOPOUND® recycling granulate as an example to demonstrate just how well the use of recycled materials in injection molding works. The KURZ subsidiary BAIER will decorate watering cans made from 100% RECOPOUND® in a high-quality and sustainable manner on a BAIER BECORUN machine via hot stamping live on site.

Strong partners for a strong trade fair presence

The bundled competencies within the KURZ Group enable the development of holistic solutions. These include surfaces with Shy Tech designs from subsidiary BURG DESIGN, integrated, wafer-thin touch sensors from subsidiary PolyIC, and the innovative tool technology from Schöfer GmbH, as well as machines from KURZ subsidiary BAIER. In addition to the exhibits and live demonstrations at our own stand, KURZ will also be presenting other joint projects at various partner stands at K 2022. In addition, the KURZ subsidiaries SCRIBOS and KURZ Digital Solutions will have their own stand (Hall 5, Stand E09) and will be presenting product and brand protection innovations. These will include the Digital Product Passport, in which both sustainability information about a product and security features can be integrated.

KURZ at ARBURG - efficient technologies for recycled plastics

At ARBURG Stand A13 in Hall 13, visitors can experience two efficient KURZ processes as part of a live demonstration: Hot-stamping and insert-molding technology. Here, toolbox components will be manufactured and refined - partly from the post-industrial recycled material RECOPOUND®.

KURZ at Deckerform - robust plastic components made from recycled materials

With RECOSYS®, KURZ is the world’s first company in the plastics industry to introduce a PET take-back system in which the transfer carrier residues are recycled into a high-quality compound granulate - RECOPOUND®. This can then be used to manufacture robust plastic components through injection molding. For this purpose, the production and finishing of a transport box made of RECOPOUND® material will be demonstrated live at the Deckerform partner stand (Hall 13, Stand B77).

KURZ with ENGEL - revolutionary technologies and automotive highlights

Together with machine manufacturer ENGEL and tool technologists from KURZ subsidiary Schöfer, KURZ is presenting the rear-end cover, a future-proof design concept for vehicle rears. The large component is manufactured from two plastic parts in a single process step and decorated simultaneously in the IMD process. It offers structures for 3D light effects, three-dimensional component geometries, and targeted light barriers.

KURZ at WITTMANN Group - overhead light console for the roof-lining

At the WITTMANN Group partner stand (Hall 12, Stand F23), a joint project from the automotive interior design sector will be produced live: The Overhead Light Console (OHLC). Thanks to its in-mold electronics, it can be used to control various functions such as the ambient light, reading light, and sliding roof. In this way, injection molding and integration of PolyTC® sensors as well as decorations are combined in a single, highly efficient work step to form a 3D-deformed component using IME. This creates a seamless organic surface in an appealing Shy Tech design with maximum creative freedom.

Partner project of KURZ and Polyscope Polymers at the Bayern-Innovativ Stand

Bavarian companies and research institutions will be presenting their latest developments at the Bayern-Innovativ joint stand (Stand C36, Hall 12) at K 2022. LEONHARD KURZ and its partner Polyscope Polymers will also be there with their electronic applications and technical polymers. Both experts have pooled their expertise to make the decoration of polyamide components even more upscale. Visitors can see this for themselves thanks to a demonstration device and a door strip made from Polyscope material and decorated with KURZ processes.

Detailed information on the various areas as well as KURZ projects and exhibits can also be found in the other press releases, which are available on our press page: www.k22.plastic-decoration.com/...

At a glance

K 2022 from October 19-26, 2022

LEONHARD KURZ Stiftung & Co. KG: Hall 5, Stand A19

KURZ Digital Solutions + SCRIBOS: Hall 5, Stand E09

KURZ and Polyscope Polymers at Bayern-Innovativ: Hall 12, Stand C36

KURZ at ARBURG GmbH & Co. KG: Hall 13, Stand A13

KURZ at DECKERFORM Technologies GmbH: Hall 13, Stand B77

KURZ with ENGEL Austria GmbH: Hall 5, Stand A19

KURZ at Sumitomo (SHI) Demag Plastics Machinery GmbH: Hall 15, Stand D 22

KURZ at WITTMANN Group: Hall 12, Stand F23

Product group: Machines and equipment for finishing, decorating, printing, and marking

Focal points of the LEONHARD KURZ trade fair appearance: Automotive interior/exterior, consumer electronics, home appliances, sustainability