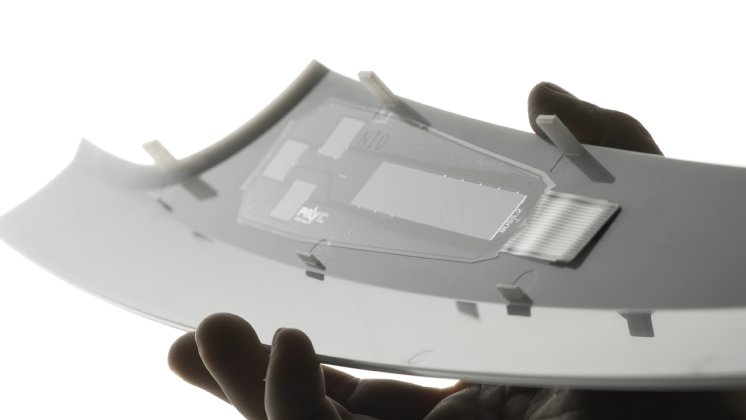

Using a new process called IMD PUR, Kurz will demonstrate the combined use of IMD (in-mold decoration) and PUR (polyurethane) technology for automotive applications. A front panel will be decorated and overflooded with PUR in the same clamping unit on an Engel duo 2460/900 injection molding machine. The novel design effects that can be achieved with this process will be demonstrated at the trade fair booth by means of a radiator grill concept. Aside from having an avant-garde design, this concept also illustrates the technical feasibility of using the process for exterior applications. The cutting edge surface design of the demonstrator is equipped with functions for autonomous driving that were jointly developed with the LiDAR (light detection and ranging) sensor manufacturer Velodyne.

Kurz will also be demonstrating future-oriented concepts for automotive interior controls by means of a touch-control steering wheel – developed in a technological partnership with GE-T – with haptic feedback and freely programmable operating functions.

Mechanically integrating touch sensors

A highlight of the trade fair booth will be the fully automated integration of touch sensors from the Kurz subsidiary PolyIC into a whitegoods panel using FFB (functional foil bonding). The FFB process, which has been patented by Kurz and was presented for the first time at Fakuma 2018, has since made the leap to series production. FFB can be integrated into automated production lines and linked with their materials management system. At the Kurz booth A19 in Hall 5, a machine from the Kurz subsidiary Baier will equip a panel with large-area sensors for touchscreens at industrial speeds.

A multi-function demonstrator cover will illustrate the advantages of these sensor control panels for series production. Different household appliance models can be equipped with the same components, and with buttons that are fully configurable. This allows this platform concept to make small runs with custom programming economically viable.

Individualization and metallic look on plastic tubes

Sophisticated and attention-grabbing designs will be applied to cosmetic containers at high speeds in a live demonstration on a printing and finishing machine from the Kurz subsidiary Isimat. The machine is equipped with two processing stations for indirect digital printing and metallization which can be used to print individualized designs with extraordinary metallic effects. A series of holographic designs with a relief or depth effect, which can turn the cosmetics packaging into a real eye-catcher and underscore the brand’s value, will also be presented.

Materials and colors combined in surprising ways

Kurz has several innovative design ideas for the consumer electronics sectors. Mood-setting day/night effects as well as large-area and partial backlighting create a symbiosis of light and color design. Sleek soft touch surfaces or tactile structures combined with modern colored designs allow the optics and haptics to meld together. Eccentric holographic effects convert surfaces into 3D spaces. Futuristic exhibits invite designers and manufacturers to go on a voyage of discovery.

Kurz in the VDMA Pavilion

At K 2019, the VDMA will be setting up a central contact and information point on the topic of the circular economy in an outdoor area in front of Hall 16. Kurz will be providing detailed information in this area on its contribution to a sustainable circular economy. The company would like to present some facts and figures to prove that the decorative coatings from Kurz do not impact the recyclability of plastics. Decoration solutions to visually enhance recycled plastics will also be presented. In addition to this, background information on a successful project for decorating parts with recycled content will be available. Visitors will be able to see a live application using Kurz coatings at the Engel booth B42 – C58 in Hall 15.