October 21, 10:00AM – 11:00AM CEST:

IMD PUR – Global innovation for automotive surface design

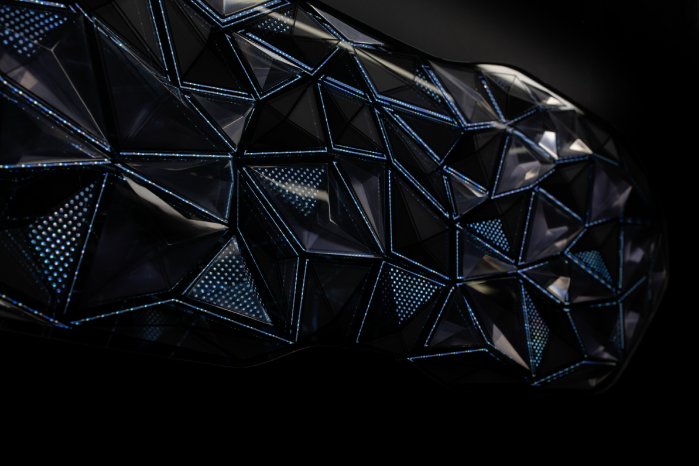

Developers of front panels for electric and autonomous vehicles must dress smart technology in sophisticated design. The new Kurz process, IMD PUR, provides new opportunities. It allows for brand-shaping dead-front panels and radiolucent surfaces that are also durable and self-healing.

The online seminar will explain the new process, which allows IMD decoration and flooding with PUR (polyurethane) in a single step. Participants learn why IMD PUR provides more options in the design of automotive fronts. The online seminar will also get into technical specifications and tests. It will be presented by Fabian Bürkel, Project Engineer Technology and Innovation Management in the plastics division at Kurz.

October 28, 2020, 10:00AM – 11:00AM CEST:

FFB (Functional Foil Bonding) - Sensor integration with highest precision

How can durable touch sensors be applied cost-effectively and without adhesive to operating interfaces? Kurz makes this possible with its patent pending FFB (Functional Foil Bonding) process. FFB allows, for the first time, mechanical integration of touch sensors. The online seminar is directed at technical experts in the automotive, home appliances, and consumer electronics industries.

Together with Dr. Wolfgang Clemens, Head of Product Management PolyTC at Kurz subsidiary PolyIC, online seminar participants will get a peek behind the scenes of process development. These include: How touch sensors are integrated into plastic parts by using FFB. Where the FFB process is superior to the OCA and PSA techniques. What the technical specifications are. Dr. Clemens will explain how the process handles volume production based on a solution from the automobile industry.

November 11, 2020, 10:00AM - 11:00AM CEST:

Innovative HMI solutions by integrating metal mesh sensors into plastic surfaces

Dead-front control panels equipped with the latest technology and boasting sophisticated design and cost-efficient production. What sounds like a demanding requirement profile becomes possible. The online seminar will demonstrate this using the example of an award-winning HMI instrument panel that Kurz developed for an automobile interior.

The online seminar is oriented toward persons in the automotive, home appliances, and consumer electronics industries who would like to use more touch panels and touchscreens. They will learn how to cost-effectively furnish an instrument panel with sensors for controls navigation, backlighting, touch operation and slider action, and at the same time with a sophisticated design. It also involves all process components used in the HMI concept: IMD, FFB, IML and lamination. Jörg Stierand, Head of Sales Management Automotive Europe and Head of HMI at Kurz, will host the event.

November 18, 2020, 10:00AM - 11:00AM CEST:

Making every product unique – Home appliances decoration and function

The production of smart home appliances is not necessarily linked to high costs. On the contrary, by combining decoration and touch control, some components and production steps can be eliminated, which lowers production costs. At the same time, touch panels make the devices more attractive, as backlit dead-front designs and simplified control functions become more popular.

In the online seminar, participants from the field of home appliances learn how to cost-effectively produce design-oriented touch controls. Using the volume production of washing machines as an example, Kurz specialists will demonstrate how to inexpensively produce components with different language and model variants. On the agenda as well: How to combine function with backlighting. The online seminar is hosted by Steven Hirschberg, Project Engineer, Plastic Decoration at Kurz and Johannes Schad, Product Manager at Kurz subsidiary PolyIC.

Registration for all seminars at www.plastic-decoration.com/....