Future-proof design for autonomous driving and e-mobility

Autonomous vehicles require materials that permit LiDAR and radar beams to pass through. They also have to be enormously durable when used externally. To satisfy these requirements, while at the same time expanding the design scope, Kurz has developed a new decoration process called IMD PUR. In this process, an injection molded part is produced, decorated with an in-mold design, and overflooded with PUR (polyurethane) all in the same clamping unit. IMD PUR delivers the best of two worlds in a single production step: the design quality and flexibility of IMD technology as well as the depth effect and glassy appearance of PUR coatings. This process can be used to produce surfaces that support radar and LiDAR functions while also possessing a distinctive and brand-shaping design.

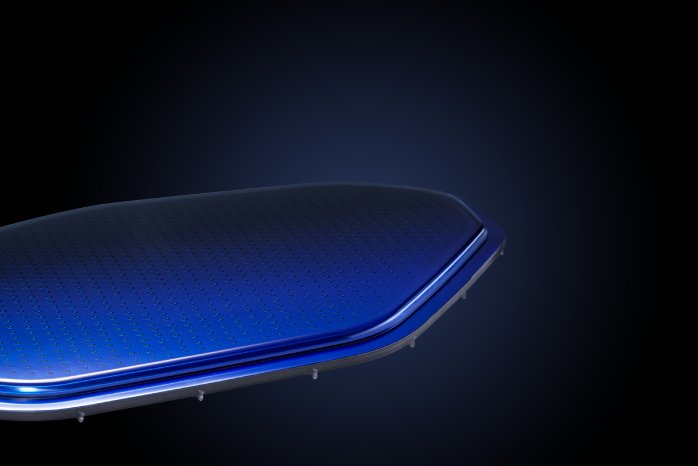

The IMD designs can contain expressive surface structures that remain visible after being overflooded with PUR. This enables sophisticated structured designs to be created in combination with a smooth, aerodynamic and non-hazardous surface. The designs can be used to produce solid but still visually relaxed or backlit front panels that are optimally suited for electric cars. The PUR-coated surface also meets the necessary durability requirements for exterior use and offers a high level of surface protection. The decoration remains intact when subjected to scratches or stone impact, and the PUR topcoat is self-healing when scratched.

Visitors to the Kurz booth will be able to see a live demonstration of the IMD PUR process on a duo 2460/900 injection molding machine from the company Engel with the recently developed IMD PUR die technology from Schöfer. A front panel will be produced with a single-image design containing a gradient from black to blue and an internal structure visually emerging out of the depths of the PUR coating.

Playing with light and reflections

The IMD PUR process supports a variety of design transfer methods. Roll-to-roll IMD technology can be used to perform the decoration during injection molding with subsequent PUR flooding, or alternatively single sheets can be processed using the PMD (Print Mold Design) method.

Kurz will be presenting IMD PUR designs produced using the roll-to-roll process that exhibit special light effects. Sophisticated lighting design has not only found its way into automotive interiors but will also shape the exterior design in future. Kurz has developed backlit IMD designs for front panels that give auto brands a distinctive identity. At the Kurz booth, a concept panel will be presented with shape-following structures accented with backlit openings. A metallic-like, reflective color alternates with a saturated green which transforms into a deep blue as the incident light changes. The eccentric single-image design of the panel gives vehicles an unmistakable face.

Surface with pronounced 3D appearance

Kurz will be demonstrating IMD PUR processing of PMD single sheets by means of surface designs that were developed by Kurz subsidiary Burg Design.

The pre-formed sheets decorated by silk-screen printing will be individually placed into the mold, fused to the part during the injection molding process, and then overflooded with PUR. By employing the silk-screen printing technique and printing the sheets on both sides, it is possible to produce a special 3D effect using PMD. When this is then combined with the IMD PUR depth effect, designs with a unique spatial effect are created. At K 2019, backlit single-image designs with superimposed structures will be presented that exhibit a pronounced three-dimensional appearance and fascinating simulated depth.

All these front panels with their innovative surface designs will be on display at the Kurz booth A19 in Hall 5.