Public corporation Profiblech AG, located in Kägiswil, Switzerland, has been processing sheet metal parts of varying sizes successfully, since their formation in 2008. With 12 employees, Profiblech has been promoting its core business in laser cutting and chamfering, including post-processing edge finishing work, with a main focus on fulfilling and exceeding customer expectations. Applying their vast experience and devotion to their business, they are dedicated to processing each part to perfection. (Picture 1).

Profiblech AG’s customers are primarily businesses in the construction and automotive industries, located throughout Switzerland. Profiblech creates value by applying their own high demands on quality, efficiency, and flexibility in an effort to fulfil their customers’ requirements. And more than that – in performing their services, production manager Walter Erni (Picture 2) emphasizes, they strive to be “a step ahead” of the customer. Top priority is always to supply the customer the “perfect metal part for subsequent processing steps” (Picture 3). Towards this purpose, Profiblech AG gladly offers their customers a preview of their capabilities. Especially for new customers, Erni stresses, “deburring all sheet metal parts is standard procedure”, to properly highlight the full potential of high-quality sheet metal processing.

A machine for deburring and edge rounding

Customer demands as well as their own requirements for high-quality products and efficient production processes played an equal role in Profiblech’s decision to invest in an SBM-L 2000 G1S2 deburring and edge rounding machine from LISSMAC Machinenbau GmbH in Bad Wurzach, Germany. Due to the positive experience they have had with LISSMAC in the past, and the fitting solution that was available by the German engineering company, it was obvious, according to Walter Erni, that the 2,000 mm wide machine by LISSMAC was the “only way to go”. The combined benefits of a working width of up to 2,000 mm, and its innovative double sided operating method, provide optimal processing results for the full spectrum of applications (Picture 4).

Custom version – 2,000 mm working width

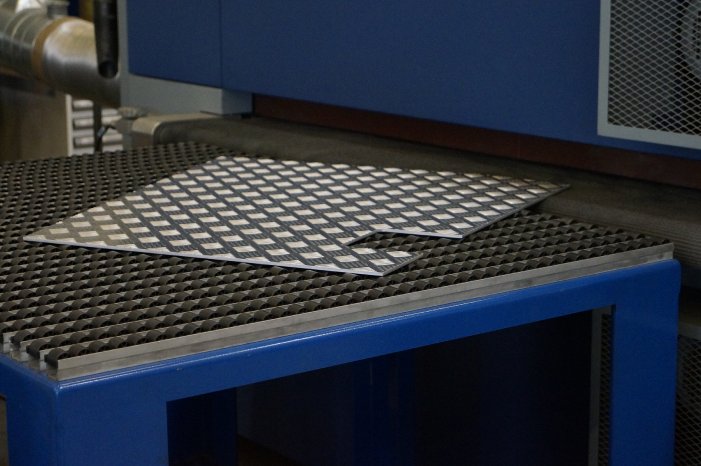

The capability of processing sheet metal parts of widths up to 2,000 mm nicely rounds out the performance spectrum of this Swiss sheet metal services company. Matching the rest of its factory equipment, including their high-bay warehouse, laser cutter, and press brake, which are all designed for lengths up to 2,000 mm, this SBM-L 2000 G1S2 custom version machine completes Profiblech’s machinery park and optimizes their range of services, dedicated to quality and flexibility. This LISSMAC custom design addresses the special needs regarding the dimensions of the in- and out-feed belts, as well as the tool belts (Picture 5). The increased feed width of the machine allows for an even and high-quality deburring and edge rounding process, even for very large parts (Picture 6).

The superior processing results and efficient operating method of their first LISSMAC machine convinced Walter Erni to invest in another LISSMAC system. The capability of offering two differently configured steel processing machines now enables Profiblech AG to provide the full spectrum of steel processing services (Picture 7).