Collaborative welding solutions have become a guarantor for success for small operations and medium-sized enterprises. They can be used to weld not only small and medium-sized series simply and automated to be highly economically efficient. They also relieve the welders in hard everyday work and keep on compensating for the increasing shortage of skilled labour. With its myCobot modules, Lorch is now offering an even simpler and more targeted entrance into the world of collaborative welding. In future, companies can custom-assemble their automation solutions from the Cobot Welding World, tailored to their specific welding tasks and requirements.

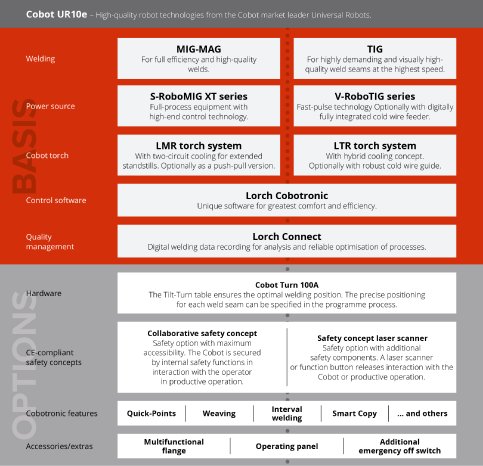

In addition to the basic equipment of the system with the new Cobot UR10e, the Lorch Cobotronic control software, and Lorch Connect for digital welding data analysis, the respective power source and the matching torch can be selected based on welding procedure (MIG-MAG or TIG). The customer can flexibly decide whether they want to integrate additional hardware, such as a turn-tilt table or a multifunctional flange, into the system. Multiple safety systems are available, depending on demand.

The core of the Lorch Cobot Welding World – the Lorch Cobotronic software – has been clearly expanded. It is now available in twelve languages, offering many practical additional functions such as interval welding, weaving, or a spot function for easier tacking. Even faster access to the most important functions of the control software is offered by the QuickAccess menu as a program feature, or by using the expanded Cobot Jobs assistant: This additional feature can be used to save parameters and settings of recurring weld seams as favourites and call them up again on demand using the corresponding keywords. This saves time and facilitates work even for less experienced welders.

The Quick-Points functionality allows you to directly assign points along the path and insert welding commands by the push of a button to teach complex parts in the least possible time. The Smart Copy function, which is also new, permits you to simply copy a programme for an existing part and utilise the programme for the same part but in a different area of the workspace. Performance and the produced quantity can be quickly increased by a factor of 3 to 4 this way.

Lorch Schweißtechnik ensures optimal future-proofness with the comprehensive upgrade capacity within the Cobot Welding World: If the requirements to the welding task, and thus the demand in new functions change, the system can be expanded with the corresponding options and extras at any time. This also applies to new functions that are added by the continuous development work of the Lorch software specialists.

Even more intuitive, precise, and comfortable: The UR10e provides a Cobot of the latest robot technology. In use at Lorch since 2022, it not only offers improved repeat accuracy and easier free-drive for simpler guidance and positioning of the Cobot arm, but also has safety limits optimised to increase the movement speed between the individual weld seams to shorten the processing times yet again. A new multifunction flange at the Cobot head with three buttons that can be freely assigned now allows input of programming steps right at the robot. Programming is once again clearly simplified and sped up this way.

The Lorch services connected to installation of a system, which have been in high demand among the customers already, are further intensified. Lorch is covering the entire area, from competent initial consulting, compilation of an optimised and harmonised system, to setup, commissioning, and training of the employees. Ongoing customer service is warranted by qualified Cobot partners both in and outside of the country. Various financing models from the financing plan to the option of renting of a Cobot system open up attractive options for companies to find a simple entrance into automation.

Caren Dripke, department head of robotics development at Lorch Schweißtechnik: “With the new Lorch Cobot Welding World, we are offering companies a comprehensive range of components, functions, and supporting features. Our myCobot modular system lays the foundations for a wide application of collaborative welding solutions, opening up a new dimension for automated production. As a market leader in the area of Cobot solutions, we ensure long-term investment protection and greater flexibility, which are particularly important for small and medium-sized enterprises.”