Thermoset or thermoplastic CFPRs?

Frequently asked questions about carbon fiber composites concern the selection of the matrix system, the most suitable processing technology and the resulting cycle time, energy need, cost effectiveness, and static and dynamic performance of these components. The project MAI Qfast is compiling answers to these questions.

Ambitious floor panel structure as demonstrator

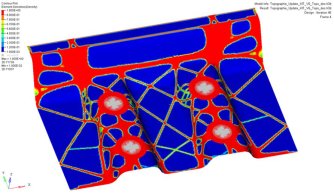

As the main focus of MAI Qfast is a comparison of the specific potential of thermoset and thermoplastic CFRPs for largescale production it was important that the chosen demon-strator - an ambitious floor panel structure - could be produced using either RTM or compression molding technology. Five different CFRP-materials and three different processes (RTM, SMC and LFT-D) have been developed for benchmarking, and for a demonstrator derived from a floor panel structure. The influence of the technology, the material and the component geometry on the cost and performance and the applicability in large-volume production is of major importance for OEMs and their suppliers. Only commercially-available materials have been used to ensure a complete comparability. During the whole project the engineering work was accompanied by simulation.

Compression molding or RTM?

The compression molding processes are represented by thermoset sheet molding compound (SMC) and direct long-fiber-reinforced thermoplastics (D-LFT), both combined with continuous fiber reinforcements to improve the mechanical properties. Beside the compression molding processes, the RTM process using a thermosetting epoxy, a thermosetting polyurethane and a thermoplastic polyamide as resin was selected. For the comparability of these processes one type of carbon fiber was chosen and used for each technology. Only slight modifications, such as the sizing of the fiber, were carried out.

Comparability of the benchmark

The same type of carbon fiber (with adapted sizing) was used for all trials, either in thermoplastic or thermosetting resin, as well as for the production of semifinished sheets for sheet molding compound (SMC) processing. As a benchmark for the carbon fiber SMC, the long fiber thermoplastic direct process (LFT-D) based on carbon fibers was performed. The LFT-D process combines an in-line compounding unit with a subsequent compression molding unit. Fibers and resin are gravimetrically dosed and homogenized in the extruder. Meanwhile the unidirectional reinforcing tapes are heated up and brought into the shape of the demonstrator. The extruded D-LFT material is placed in the mold together with the carbon fiber structure and pressed to the final part. After demolding, post processing (for example trimming) is required, depending on the application.

For the third alternative, the RTM process, the carbon fibers were processed to form a non-crimp unidirectional fabric. In this process, several layers of the textile are stacked together, heated and formed to a stiff 3D-shape - a socalled preform. For comparability the stacking of the preforms is adopted for all RTM resin systems. The preform is then placed into the mold, the mold closes and the preform is infiltrated. After a certain curing time the part can be demolded.

Demonstrator production

The demonstrator parts for the RTM and the two compression molding processes differ in some details (e.g. ribs at the compression molded parts) according to the material involved, but fit in an identical design space. Before investments were made in mold hardware, the component design was analyzed and optimized using the mechanical properties of the selected CFRP systems, which were determined through the characterization of test specimens.

The demonstrator parts produced will now be tested, evaluated and validated in the next phase of the project.

This report is based on results achieved in the MAI Qfast (03Mai05) project of the MAI Carbon Leading-Edge Cluster. This project is funded by the German Federal Ministry for Education and Research, and managed by the Project Executive Agency in Jülich.

About the Fraunhofer ICT and the Polymer Engineering Department

The Fraunhofer Institute for Chemical Technology ICT is one of the 67 institutes and research centers that currently make up the Fraunhofer-Gesellschaft. Beside contractual research for industry, the Fraunhofer ICT also works together with commercial enterprises in research projects co-funded by the German government and the European Union.

The Polymer Engineering Department is one of the leading application-related research institutions in polymer development. The Institute's employees, who mainly have an engineering background, work together with partners and customers on novel networked process steps, and continuously broaden the application fields of contemporary polymer materials. The department offers research and development services from the initial idea to the manufacture of prototypes - all in one location.

Further information at: www.ict.fraunhofer.de