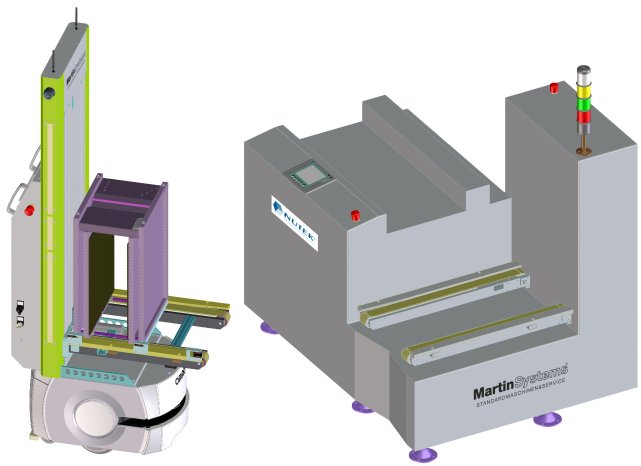

The autonomous mobile robot, developed by MartinSystems' highly qualified team of engineers, impressively demonstrates the future of industrial automation. By navigating precisely and working efficiently, the robot ensures a smooth material flow, increasing productivity and efficiency in modern production facilities.

The integration of the autonomous robot into SMD production lines in combination with the Nutek Magazine Loader opens up new possibilities for flexible production, minimizes downtime and maximizes capacity utilization. This innovative solution helps to strengthen our customers' competitiveness and future-proof their production processes.

As a company, MartinSystems stands for the highest quality and innovative strength. Our motto “We build machines for your success through a productive future” reflects our claim to develop customized solutions that help our customers to be successful.

Visit our booth at the LogiMAT trade fair to see the autonomous mobile robot live in action and learn more about MartinSystems' advanced technologies. We look forward to shaping the future of manufacturing together with you.

For more information, please make an appointment with our team on site or visit our website at www.MartinSystems.eu.

AUTOMATION FROM A MODULAR SYSTEM

Standard automation at the highest level: this is the declared corporate goal of MartinSystems. The sister company of special machine manufacturer MartinMechanic, which was founded over 50 years ago, offers a unique modular system for the automation of production processes and intralogistics for various industries and their suppliers.

The MartinSystems product portfolio consists of standardized automation cells, induction hardening machines, tool storage systems for machine tools and intralogistics solutions based on autonomous mobile robots - all of which are also available as turnkey solutions. Among other things, the compact standard systems can automatically load and unload, load, pre-rate, store and output parts. Induction hardening machines are used wherever workpieces are hardened, soldered, annealed or shrunk. And with the help of tool storage systems, machine tools can be expanded to save space and costs. Autonomous mobile robots offer clever intralogistics solutions that can supplement or replace traditional distribution concepts.

Standard automation systems offer sophisticated solutions for many applications that can be integrated quickly and cost-effectively into existing production processes.