The PSB401010H ceramic-packaged all-solid-state battery, which started mass production in June last year, has been well received for its ability to operate in high temperature ranges that are impossible with existing lithium-ion batteries. Through adoption and sample evaluations in a wide variety of fields, we have received many requests for usage beyond the upper limit temperature of 125°C for the PSB401010H. Specifically, these requests come from areas such as medical sterilization processes, semiconductor manufacturing processes, and automotive applications, where it is necessary to sense and monitor the temperature of equipment surroundings and other information in high-temperature environments.

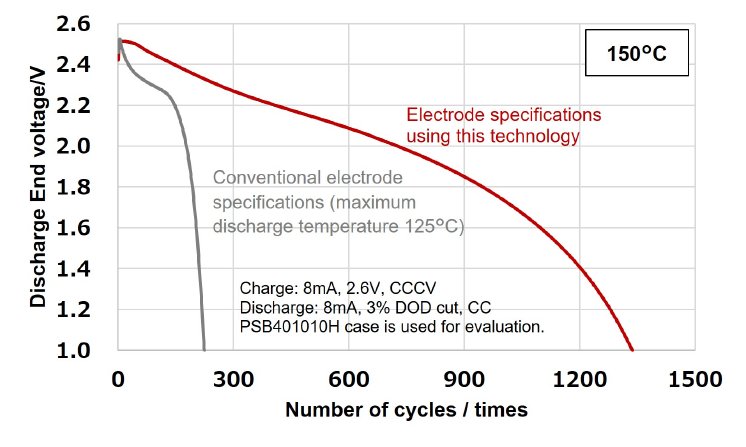

In response to these demands, Maxell has been developing improved heat resistance to expand the applicable range of all-solid-state batteries. Through the analysis of degradation mechanisms in all-solid-state batteries, we have discovered that the side effects at the interface between the positive electrode active material and solid electrolyte are the main cause of deterioration of all-solid-state batteries at high temperatures. Based on this finding, Maxell has successfully improved the number of cycles in repeated charge/discharge cycle tests at 150°C, where the discharge voltage drops to 1.0V, to approximately 5 times*1 that of conventional electrode specification products by making significant changes to the electrode design, including the electrode materials and composition. Utilizing this technology in product development will lead to a reduction in the frequency of battery replacement caused by reduced battery life under high temperatures. Additionally, the ability to perform sensing and monitoring in high-temperature environments enables more precise equipment control, leading to improved production yield and quality.

In order to solve various social issues, Maxell is developing reliable, high-performance all-solid-state batteries that can be used in areas where existing batteries cannot be used, by focusing on the following four facets: long lifetime, high temperature resistance, high output, and large capacity. Moving forward, Maxell will continuously enhance its lineup of all-solid-state batteries and also explore module products that integrates all-solid-state batteries and technologies such as wireless power supply and energy harvesting, aiming to contribute to solving social issues through our products.

*1 Approximately 5 times: Compared to PSB401010H ceramic-packaged all-solid-state battery. News release on July 25, 2022 "Maxell Commercializes High-capacity Ceramic Packaged All-Solid-State Battery"

https://ssl4.eir-parts.net/doc/6810/ir_material4/188372/00.pdf

All-solid-state battery webpage

https://biz.maxell.com/en/rechargeable_batteries/allsolidstate.html