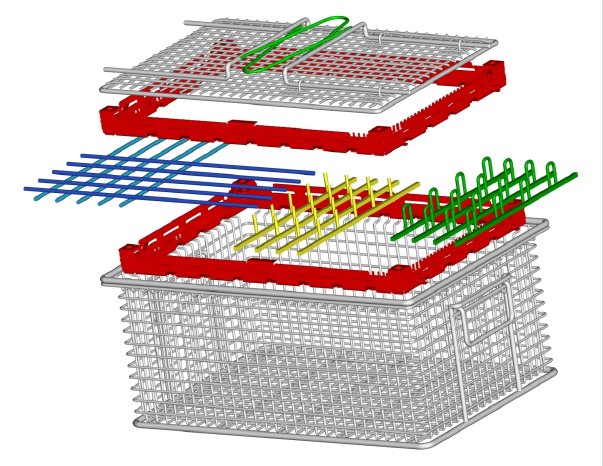

The flexible MEFO-VARIO workpiece holder system consists of a base frame with laser-cut grid, compartment separators, pin inserts and loop inserts. Plus, the trays from the MEFO-BOX system, which can be employed in many different areas, are structured using the MEFO-BOX as the base and, if necessary, the adjustable lid.

To make it quicker and easier to fix the base frame into the MEFO-BOX, it now has engaging pins at the front with a spring mechanism on one side. The frames can be fixed in place in the 15 mm grid. In addition to the simplified handling, the new fastening solution increases process reliability, especially with swivelling or rotating movements during the cleaning process.

Alongside the existing compartment separators, pin and loop inserts are now available, making the MEFO-VARIO system significantly more versatile. As the new inserts are each equipped with several welded pins or loops, only a minimal setup time is required for building complete pin and loop trays.

Quickly adjusted to the appropriate range of parts

To assemble parts-specific tray compartments, the compartment separators are simply laid into the grid of the base frame and fixed in position using a ball latch. Pin and loop trays adjusted to the component can be created quickly using the new pin and loop inserts. Simply fasten the inserts crosswise to the grid of the base frame using the ball latch. You can form different levels by using several base frames with the necessary accessories. The manufacturer maintains a stock of these standard components, which ensures fast availability.

The new MEFO-VARIO also offers advantages for companies that produce different parts in small series. The very easy handling means that the compartment, pin or loop trays equipped for specific parts can be altered with minimum effort.

High grade processed stainless steel

The MEFO-VARIO system is produced from stainless steel with an electrolytic polished surface, as are all cleaning baskets from Metallform. This high-grade material guarantees a long service life of the tray systems, rules out any soiling of the component from the workpiece holder and prevents corrosion and zinc deposits in the cleaning tanks. The use of rods also reduces the contact surfaces, improves accessibility for the cleaning fluid and optimises draining behaviour. The finish of the MEFO-VARIO has been engineered down to the finest detail. All components are welded. There are no sharp edges or burrs, so filling and emptying the boxes is completely safe. And for cleaning particularly sensitive parts, any surfaces that come into contact with the parts can be optionally halar coated. Special Teflon clips are also available for component protection. They allow targeted encapsulation of the compartment separators or loop inserts that come into contact with the workpiece.

Please contact Metallform Wächter GmbH, Gewerbestraße 35, D-75015 Bretten, Germany for more information. Tel: +49 (0)7252 9426-0, Fax +49 (0)7252 9426-11, www.metallform.de

We would be grateful to receive a copy of any publication featuring content from this release.

Contact for editorial offices:

SCHULZ. PRESSE. TEXT.

Doris Schulz

Martin-Luther-Strasse 39

70825 Korntal, Germany

Tel: +49 (0)711 854085

Fax +49 (0)711 815895

E-mail ds@pressetextschulz.de

Member of Absolut … Network

METALLFORM Wächter GmbH

Anja Wächter

Gewerbestrasse 35

75015 Bretten, Germany

Phone: +49 (0)7252 9426-10

Fax +49 (0)7252 9426-810

E-mail anja.waechter@metallform.de

www.metallform.de