Enhance reliability and simplify assembly

Stäubli is constantly expanding its product line for railway technology, especially in the field of modular connectors and multi-couplings. As a highlight at InnoTrans, Stäubli presents the latest addition to the assortment of the Modular Power Connector (MPC): a new model in smaller size to address further applications. With its modularity, safe and most reliable high-power transfer, the MPC fits for all on-board power applications for inter-car connection on the roof or under the cars, traction converter and battery outputs, body to bogie and motor connection on rolling stock in most demanding requirements.

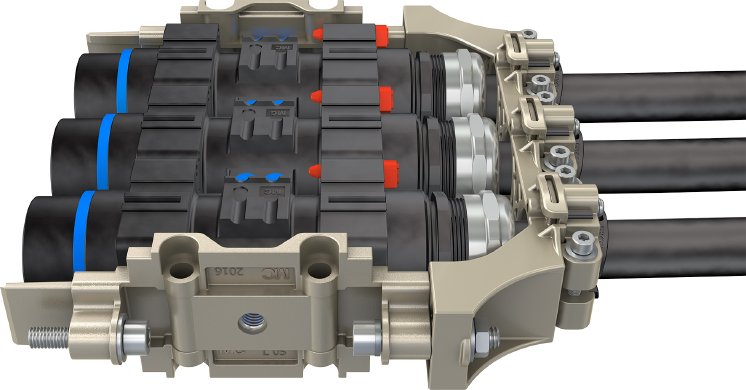

To enhance reliability and longevity, the new Dynamic Cable Option (DCO) is being attached directly to the connectors as a strain relief and replaces difficult to install strain relief brackets with clamps. To even more support fast, easy and safe installation and short maintenance time, Stäubli comes up with a Positioning and Fixing Option (PFO). This connection assistance eases the assembly process and supports the correct mounting of the MPC in narrow locations, e.g. under-car situations, and helps to guide also the connection of mobile parts.

Modular connector system

The comprehensive offer of electrical connections solutions is accomplished with battery and storage technology ranging from manual plugging to systems for automated battery charging stations. For applications with the need of connecting combinations of power, signal, data, thermocouple, coaxial, fiber optic, pneumatic and hydraulic connections within a single frame, the modular system CombiTac from Stäubli is tried and tested, even for highest mating cycles. Above the standard product lines, Stäubli develops and manufactures complete customer-specific solutions including cable assembly as fully tested modules.

A multi-connection solution for every application

Stäubli's unique expertise in coupling technology provides a proven connection solution that permits the automatic changeover of carriage bogies when the gauge size changes in the international rail network. The principle: Both the couplings for the compressed air connection and the electrical connectors for signal transmission are integrated in the system. When the carriage body is lifted from the bogie, the two connection parts are automatically separated and the circuits are then automatically connected again when the body is lowered. This ensures considerable time savings during cross-border rail travel.

To ensure the cooling of the on-board electronics, the connections for the hydraulics and electronics run together in an integrated circuit. On the one hand, the multi-coupling is equipped with fluid couplings that connect the cooling plates with the cooling circuit. In addition, the electrical connectors for connecting the electronic components are also integrated in the panel. In this case, Stäubli’s quick couplings are mounted on the customer's cooling plates at the module and act as the connection between the module and the cooling circuit in the housing. To connect the circuit, the module containing the cooling plate is simply pushed into the power converter cabinet. This all-round solution excels in particular through the ease and speed of maintenance it allows.

Connection solution for all train segments

With its industry-specific portfolio of quick couplings and electrical connectors, Stäubli provides connection solutions for all train segments in which fluids, gases or electrical energy have to be transported. These include: gangway connections, electricity consumers, brakes and pneumatic damping, filling, emptying and fill level monitoring, traction couplings, engine cooling and power transmission, door systems, fuel and drinking water circuits, air conditioning and many other applications.

Visit us at InnoTrans:

Stäubli Electrical Connectors, hall 12, booth 208

Stäubli Fluid Connectors, hall 10.2, booth 201